Section 9 - Maintenance

Quantech

173

Form QTC4-NM2

Issue date: 05/12/2023

9

Steps to touch-up end, dead tubes or

condenser coil headers

In cases where e-coating on the end tubes and/or con-

denser coil headers is showing signs of degradation,

2-part Urethane Mastic must be used for touch-up. Do

not use 2-part Urethane Mastic on finned coil surface.

Do not use 2-part Urethane Mastic on

finned coil surface. Using Urethane

Mastic on finned surfaces can result in

the blockage of fin sections which leads

to reduced airflow across the coil.

Materials required:

• 2-Part Urethane Mastic kit, part number:

013-04188-000.

• 1 x Mixing Dish.

• 3 x 3 ml droppers.

• Soft bristle paint brush.

The procedure listed below must be followed to touch-

up end tubes and condenser coil headers:

1. 2-Part Urethane Mastic kit consists of Component

A-Urethane Mastic (black component) and Com-

ponent B-Urethane Mastic Activator (clear com-

ponent).

2. Thoroughly stir the can containing component A

(Urethane Mastic). It is important to stir the Ure-

thane Mastic thoroughly to ensure any settled pig-

ment is dispersed before application.

3. Gently shake the can containing component B

(Activator).

4. Mix urethane mastic and an activator in a 5:1

ratio. Using one dropper, add 5 mm of component

A to the mixing dish.

5. Using the second, clean dropper, add 1 ml of com-

ponent B to the mixing dish.

6. Mix the components well and allow the solution

in the dish to set for 30 min. Power mixing is pre-

ferred. If needed, make more amount of solution

for application.

7. Using the paint brush, apply the touch up paint to

the end tubes or coil headers as needed.

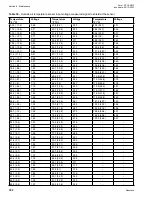

Table 34 -

Part numbers

Part number (P/N)

Description

013-04185-000

Cleaner, coil, 4-1 gal

013-04185-001

Cleaner, coil, 1 gal

013-04186-000

Reducer, salt, 4-1 gal

013-04186-001

Reducer, salt, 1 gal

013-04187-000

Paint, touch-up, 12 oz

013-04188-000

Mastic, 2-part Urethane

Chilled liquid system maintenance

Whenever the chilled liquid system requires mainte-

nance, adhere to and observe all the following precau-

tions.

Scheduled maintenance

The QTC4 chiller is equipped with Service Reminder

Warnings that show service reminders on the chiller

panel every 3 months, 12 months, 36 months, and 60

months from the date of last service. Ensure a quali-

fied service engineer conducts the maintenance opera-

tions on a regular basis, which is detailed in

nance requirements for QTC4 chillers on page 175

It must be noted that the interval necessary between

each minor and major service can vary depending on,

for instance, application, site conditions and expected

operating schedule. Normally a minor service must

be carried out every three to six months and a major

service once a year. It is recommended that your local

Johnson Controls Service Center is contacted for ser-

vice recommendations for individual sites.

Thermal dispersion flow switch

Check the sensor tip for buildup regularly, because it

can affect the sensitivity of the sensor.

In case of any buildup at the sensor tip, use a soft cloth

to remove it. Use vinegar as the cleaning agent to re-

move any stubborn buildup if necessary.

Chiller/compressor operating log

A chiller or compressor operating log is supplied at the

end of this section for logging compressor and chiller op-

erating data.

Summary of Contents for QTC40160

Page 22: ...Quantech 22 Form QTC4 NM2 Issue date 05 12 2023 This page is intentionally left blank...

Page 94: ...Quantech 94 Form QTC4 NM2 Issue date 05 12 2023 This page is intentionally left blank...

Page 100: ...Quantech 100 Form QTC4 NM2 Issue date 05 12 2023 This page is intentionally left blank...

Page 158: ...Quantech 158 Form QTC4 NM2 Issue date 05 12 2023 This page is intentionally left blank...

Page 187: ...Quantech 187 Form QTC4 NM2 Issue date 05 12 2023 This page is intentionally left blank...