7

Figure 4. Interaction between Quanser Aero 2 system components

Handling and Setup

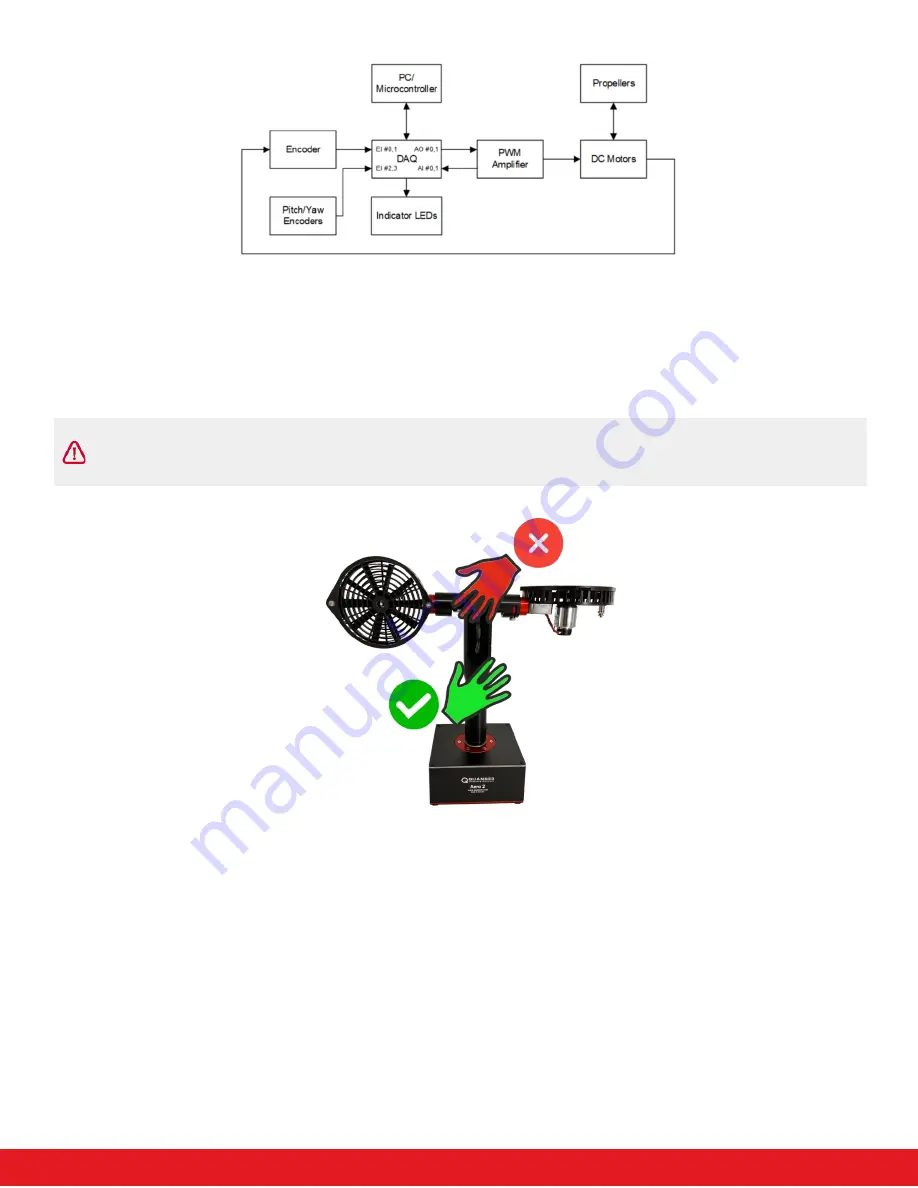

When moving the Quanser Aero 2, lift it by gripping the support yolk just above the yaw pivot. Support the base with

your other hand.

Warning

Do not lift the Aero 2 by the Aero body.

Figure 5. Correct and incorrect locations to lift Quanser Aero 2

To operate your Quanser Aero 2, follow these steps,

1.

Ensure that the power switch is OFF and connect the Aero 2 to a power supply.

2.

Connect the Aero 2 to the PC via USB or to the microcontroller via SPI connection.

3.

Ensure that a volume of space around the manipulator is dedicated as a work zone that users must stay clear

of. The radius of this area should be at least 0.5 m.

4.

Check that the thrusters are oriented as required and locked firmly in position using the thumbscrews.

5.

Check that the pitch and yaw locking screws are engaged or disengaged as required for your task.

6.

Switch on the power switch and ensure that the status LED on the QFLEX 2 panel is green.

7.

The Aero 2 is ready for use.