Quadra-Fire • QFP38 Series • 4061-300 Rev i • 9/09

64

16

16

Troubleshooting

With proper installation, operation, and maintenance your gas appliance will provide years of trouble-free service. If you

do experience a problem, this troubleshooting guide will assist a qualifi ed service technician in the diagnosis of a problem

and the corrective action to be taken. This troubleshooting guide can only be used by a qualifi ed service technician. Con-

tact your dealer to arrange a service call by a qualifi ed service technician.

The normal behaviors of the board could be inhibited by

the anomalies described in the following tables.

Note on the automatic ignition sequence:

• The supervised pilot fl ame detection is activated only

after a command is correctly received.

•

The sparking means are activated only after no parasitic

fl ame is detected, before the ignition.

• The pilot gas valve is energized, and the gas will fl ow,

only after the sparking means are activated.

Note:

To reset the ignition module lockout - turn the unit off for fi ve seconds, then back on.

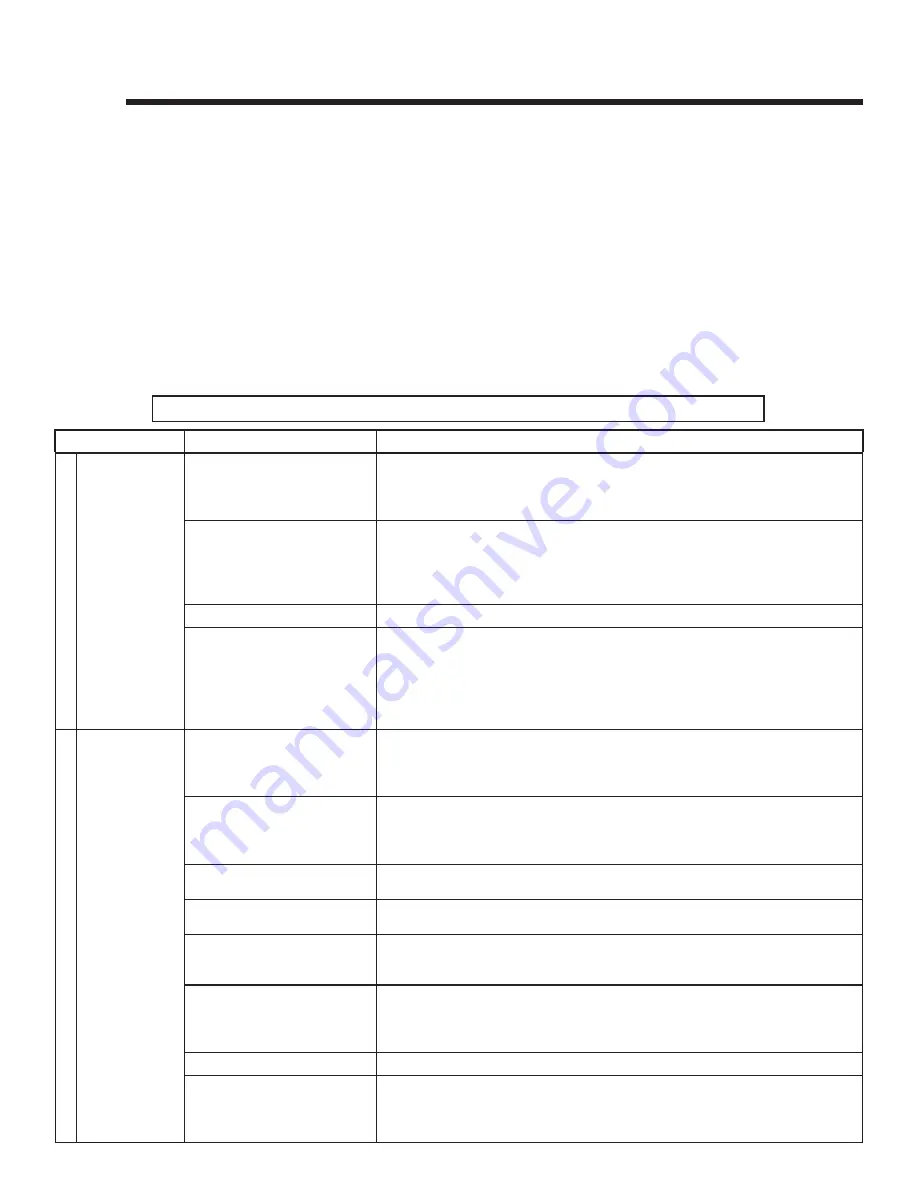

Symptom

Possible Cause

Corrective Action

1.

The ignitor/

module makes

noise, but no

spark.

a.

Incorrect wiring.

Verify “S” wire (white) for sensor and “I” wire (orange) for ignitor are connected to the

correct terminals on the module and the pilot assembly. Reversed wires at the module

may cause the system to make a sparking noise, but the spark may not be present at

pilot hood.

b.

Loose connections or

electrical shorts in the wiring.

Verify there are no loose connections or electrical shorts in wiring from module to

pilot assembly. The rod closest to the pilot hood should be ignitor. Verify connections

underneath pilot assembly are tight; also verify the connections are not grounding out

to the metal chassis, pilot burner, pilot enclosure, mesh screen if present, or any other

metal object.

c.

Ignitor gap is too large.

Verify gap of ignitor to pilot hood. The gap should be approximately .17 in. or 1/8 in.

d.

Faulty module.

Turn ON/OFF rocker switch or wall switch to OFF position. Remove ignitor wire “I”

from module. Place ON/OFF rocker switch or wall switch in ON position. Hold ground

wire about 3/16 in. away from “I” terminal on module. If there is no spark at “I” terminal,

module must be replaced. If there is a spark at “I” terminal, module is fi ne. Inspect pilot

assembly for shorted sparker wire or cracked insulator around electrode.

2.

Pilots won’t light,

there is no noise

or spark.

a.

Fireplace burner control

installed incorrectly.

Verify that fi replace burner control is installed and plugged into module. Check voltage

of transformer under load at space connection on module with ON/OFF switch in ON

position. Acceptable readings of a good transformer are between 3.2 and 2.8 volts AC.

b.

A shorted or loose

connection in wiring

confi guration or wiring

harness.

Remove and install the wiring harness that plugs into module. Verify there is a tight fi t.

Verify pilot assembly wiring to module. Remove and verify continuity of each wire in

wiring harness.

c.

Module not grounded.

Verify green ground wire from module wire harness is grounded to metal chassis of

appliance.

d.

No gas fl ow out of pilot

burner.

Check gas mains supply and pressure. Check gas valve wirings and connections to the

board. Check for pilot burner obstruction.

e.

No ionization current

established through fl ame

within ignition time.

Remove/clean eventual bridging carbon deposits betweeh the pilot burner and the

ionization rod.

f.

No gas fl ow out of pilot

burner or pilot gas presure

dropout upon main burner

gas valve opening.

Check gas mains supply and pressure. Check the correct gas type setting on the valve

and pilot burner assembly orifi ce.

g.

No spark generation.

Check parasitic pilot fl ame existence.

h.

No spark voltage reaches

the spark rod, or spark

developes near pilot

assembly.

Check for cracks in the rod ceramic insulator, replace as necessary. Check pilot

assembly wirings and spark return connections to the board.

• The main burner gas valve is energized, and gas will

fl ow, only if commanded and after the supervised pilot

fl ame is detected to be continuously lit.

• The system will try two times for ignition.

• Each try for ignition will last approximately 60

seconds.

• The wait time between the two tries is approximately 35

seconds.

• If there is no positive ignition, after two tries, the ignition

module will go into lockout.

A. Troubleshooting