Augsut 01, 2016

7039-174C

13

Discovery I

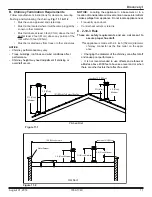

Floor

Protector

Chimney

Connector

Ceiling Support

Listed Chimney

Listed Termination Cap

Storm Collar

Flashing

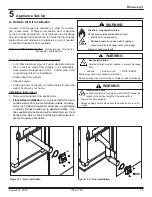

Figure 13.1 - Prefabricated Interior Chimney

Thimble

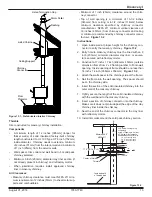

Site constructed for masonry chimney installation:

Components

• A minimum length of 12 inches [305mm] (longer for

thicker walls) of solid insulated factory-built chimney

length constructed to UL 103 Type HT 6 inch (152mm)

inside diameter. Chimney needs to extend a minimum

of 2 inches (51mm) from the interior wall and a minimum

of 1 inch (25mm) from the exterior wall.

• Wall spacer, trim collar and wall band to fit solid pack

chimney selected.

• Minimum 8 inch (203mm) diameter clay liner section (if

not already present in chimney) and refractory mortar.

• When jurisdiction requires install approved chimney

liner in masonry chimney.

Air Clearances

• Masonry chimney clearance must meet NFPA 211 mini-

mum requirement of 2 inches (51mm) to sheet metal sup-

ports and combustibles.

• Minimum of 1 inch (25mm) clearance around the chim-

ney connector.

• Top of wall opening is a minimum of 13-1/2 inches

(343mm) from ceiling or 4-1/2 inches (114mm) below

minimum clearance specified by chimney connector

manufacturer. NFPA 211 minimum vertical clearance of

18 inches (457mm) from chimney connector and ceiling

or minimum recommended by chimney connector manu-

facturer.

Figure 13.2

Instructions:

1. Open inside wall at proper height for the chimney con-

nector to entry the masonry chimney.

Figure 13.2

2. Entry hole to masonry chimney must be lined with an 8

inch (203mm) minimum diameter clay liner, or equiva-

lent, secured with refractory mortar.

3. Construct a 17 inch x 17 inch (432mm x 432mm) outside

dimension frame from 2 x 2 framing lumber to fit into wall

opening. Inside opening of frame should be no less than

14 inch x 14 inch (356mm x 356mm).

Figure 13.2

4. Attach the wall spacer to the chimney side of the frame.

5. Nail the frame into the wall opening. The spacer should

be on the chimney side.

6. Insert the section of the solid insulated chimney into the

outer wall of the masonry chimney.

7. Tightly secure the length of the solid insulated chimney

with the wall band to the masonry chimney.

8. Insert a section of chimney connector into the chimney.

Make sure it does not protrude past the edge of the clay

chimney liner inside the chimney.

9. Seal the end of the chimney connector to the clay liner

with refractory mortar.

10. Install trim collar around the sold pack chimney section.

Figure 13.2

1.5”

1.0”

2.0”

2.0”

1.5”

14.0” ID

17.0” OD

ceiling

Minimum18.0”

NFPA 211

13.5” below ceiling to top

of opening

1.0”

8.0”

1.5 2x2 framing stud

2.0 min air clearance

1.0 min air clearance

4.5

or top of opening is a min.of

4.5” below min.clearance

specified by connector mfg.

Center of Hole

Thimble

CL

CL

Wall

Include depth

of hearth pad