17

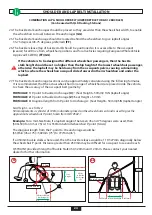

L-TRACK ANCHORAGE AND END CAPS INSTALLATION

OR

8

Parallel

8

Parallel/In-Line

8

Perpendicular

8

Perpendicular/Traverse

BOLTS

TRACK

WOOD FLOOR

VEHICLE FLOOR

WASHER

LOCK NUTS

BOLTS

TRACK

VEHICLE FLOOR

WASHERS

LOCK NUTS

I

J

K

M

• If not using Q’straint hardware, only use minimum Grade 8 bolts (reference ASTM 574 bolt specification) coated in

adequate protection against corrosion per ISO 7253 or ASTM B117

•

Refer to Table 1 - page 11, before installing the track. The track type and orientation varies for different

wheelchair securement systems. Figure I & J show track orientation

IMPORTANT

L

8

1/2” (13mm) Deep

8

L Track Length

8

1.42” (36mm) Wide

8

Floor

Determine location of Anchorages, refer to

Figure 1 & 2

1. For FLANGE L-TRACK route the floor for each track,

1.42” (36mm) wide x ½” (13mm) deep (K)

2. For END CAPS route an area in the floor for end

caps 1/2” (13mm) deep and 1.42” (36mm) wide with

semi-circular diameter to match End Cap profile (L)

For SURFACE and REGULAR L-track proceed to Step 4.

3. Clean out debris and place track in routed area

4. With track in position, use as template to mark centre

holes to be drilled.

5. Remove track and drill 8mm holes through floor per

drilling pattern. Note: Standard track drilling pattern =

holes every 4” (102mm).

6. Place sealant in floor opening (Flange L-track only)

and reinstall track

7. Pass 8mm bolt through track, vehicle floor, Backing

Plate and Washers (K & M)

Sealant may be used between Backing Plate and floor

if desired.

Recommended Torque=25 FT/LB (47 Nm)