3

Copyright © Puretec Pty Ltd 2019

Food Service Reverse Osmosis System

Safety Guides

Read and follow all steps and guides carefully before installing and using your reverse osmosis

system.

Do not use this product to make safe drinking water from non-potable water sources. Do

not use the system on microbiologically unsafe water, or water of unknown quality without

adequate disinfection before or after the system.

This reverse osmosis system contains replaceable components (membrane elements). These

components are critical for the effective reduction of total dissolved solids and specific

contaminants that are listed in the Product Data Sheet.

Consult your local public works department for plumbing and sanitation codes. Follow your local

codes if they differ from this manual.

The reverse osmosis system works on water pressures of 300 kPa minimum to 875 kPa

maximum. Water pressure can be reduced by installing a pressure reducing valve in the water

supply pipe to the RO system. A booster pump should be used for low pressure applications.

Do not install the reverse osmosis system in extreme hot or cold temperatures. Temperature of

the water supply to the reverse osmosis system must be between 4°C (40°F ) and 38°C (100°F).

Do not install on hot water lines.

All new membranes must be flushed for 3-5 minutes.

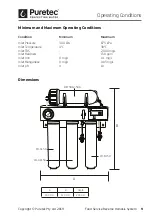

The Food Service Reverse Osmosis System

Your Reverse Osmosis System has been especially developed to achieve the perfect TDS for

your needs. The system provides three stages of filtration, the TDS bypass can then be adjusted

to allocate a portion of that water to be passed through the reverse osmosis membrane. Water

that has been treated by the reverse osmosis membrane is then combined with water that has

bypassed the membrane, allowing you to customise your TDS levels.

99.9% of minerals and impurities are removed from any water treated by the RO membrane,

the wastewater from this process is sent to drain. Any water that does not pass through the

membrane but passes through the three stages of filtration will retain valuable, flavour-

enhancing minerals.

The first stage of filtration reduces sand, silt, dirt, rust and other sediments. It then passes into

an Ultra Z filter cartridge, which inhibits limescale and reduces unwelcome elements in the

water such as chlorine, bad tastes and odours, as well as providing protection against cysts and

bacteria such as E. coli.

Safety Guides

Summary of Contents for CO-RO3

Page 12: ......