8

Food Service Reverse Osmosis System

Copyright © Puretec Pty Ltd 2019

Care and Maitenance

To Care for the RO System

The components of the RO system are designed to function with minimal maintenance.

However, the membrane elements and filters will need to be replaced on a regular schedule.

For optimal performance the system should be flushed for 2 minutes after extended periods of

inactivity.

The Reverse Osmosis System has a monitoring device for TDS. To verify that the system is

performing satisfactorily turn on the TDS Meter by pressing the RED Power button on the top

left corner. Press on the OUT button to view the Outlet TDS level.

Replacement of Prefilter and Postfilter

The carbon/sediment prefilter reduces sediment and

certain chemicals, such as chlorine, from

the water. Depending on water use and the amount of impurities, this filter should be replaced

every six to twelve months for point-of-use applications.

Whenever the prefilter is replaced, the postfilter should also be replaced.

Installations using more than 1,000 litres of water per day should install external filters (not

supplied) to reduce, sediment, chlorine and sediment larger than 10 microns.

Replacement of RO Membrane Elements

The functional life of the RO membrane elements will vary based on feed water quality. Product

water should be tested periodically to verify the membrane elements are performing properly.

For most point-of-use applications, the RO membrane elements should be replaced every two

to four years.

Note

: Softened water is recommended for optimal system performance and RO membrane

element life.

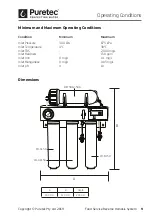

Replacement of the Prefilter, Postfilter, and RO Membrane Elements

1.

Turn off the water supply to the RO System.

2. Reduce system water pressure by opening a tap down steam, or using the holding

tank connection.

Caution

: Even with the water supply turned off the membrane and prefilter sumps will

contain a considerable amount of water. By positioning the a tray or bucket under the

system, most of the water will be contained.

3.

Undo Membrane Housing Cap by hand, and remove used membrane (pliers may be

required) Open the seal/packaging on the new membrane, insert the double o-ring end

of the membrane first. Tighten the cap by hand only. Turn the water on and flush the

system for 3-5 minutes.

Summary of Contents for CO-RO3

Page 12: ......