9

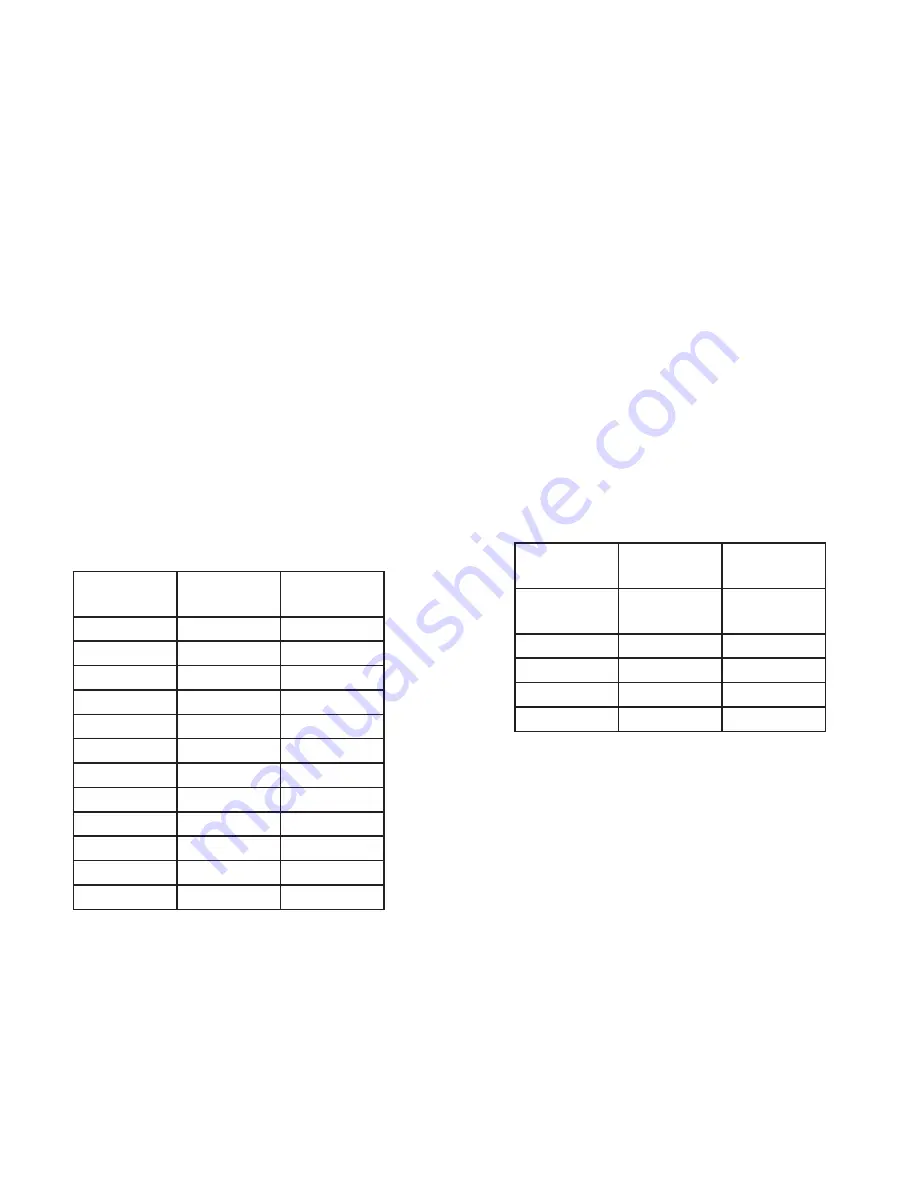

RECOMMENDED TURNING SPEEDS

WARNING. Turning too fast for the size of your work may result in injuring yourself or damaging the lathe!

Work piece

Diameter

Max RPM

Roughing

Max RPM

Finishing

1”

3600

3600

2”

3000

4000

3”

2000

2600

4”

1500

2000

5”

1200

1600

6”

1000

1330

7”

850

1100

8”

750

1000

9”

660

900

10”

600

800

11”

540

725

12”

600

660

Maximum Speeds for Balanced Turnings

Multi Speed Chart for TCLC10

Max work

piece dia.

Max Speed

Roughing

9”

Finishing

10”

610

6”

8”

1000

4”

5.5”

1450

3”

4”

2000

2” or less

2.5”

3000

Chart for TCLC10VS & TCLC12VS

Tool Rest (6)

- The tool rest is used to steady the cutting tool while the lathe is in operation. You can position the tool

rest by releasing the lock handle(28) positioned on the side of the rest and sliding the rest into the desired position.

Tighten the lock handle to secure the tool rest into position. The height of the tool rest can be adjusted releasing the

lock handle(27) located on the front of the rest and adjusting the height to the desired position and then tightening the

lock handle.

The position of the entire tool rest can be adjusted by reaching under the bed and loosening the clamp nut. Slide

the rest into position. Tighten the clamp nut. The tool rest should be positioned just above the center line of the work

piece.

Note: The lock levers are spring loaded. To operate, pull out on the lever, rotate it on the pin, and then release.

Changing Belt Speeds

-

Make sure the lathe is unplugged. Loosen the knob on the cover plate. Slide the cover up

and off the lathe. Loosen the motor plate ratchet handle (10) to allow the motor plate to swivel upwards. To change the

speed, move the belt drive from one pulley to another. (Note, Always go from the larger pulley to the smaller pulley)

After moving the belt, tighten the motor pulley with the ratchet handle (10)- this also tightens the belt. Turn your latheês

power on, and make sure that the belt is running consistently in its parallel groove (this should be done with the hand

wheel(9). If all is smooth, turn the power off, reattach the cover.

Replacing the Belt

-

The Turncrafter Commanders are designed with a special feature that allows quick and easy belt changes.

•

Loosen belt, `Remove old belt

•

Slide the new belt over the headstock spindle pulley and onto the motor pulley.