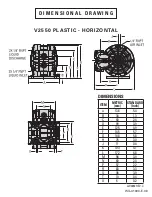

V2550 PLASTIC - HORIZONTAL

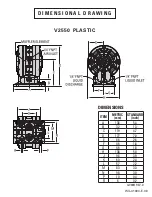

V2550 PLASTIC

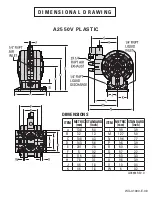

A2550V PLASTIC

MATERIAL

DIAPHRAGMS

(2)

DIAPHRAGM

BACK-UP

SEAL

(2)

POLY BALL

CHECK

CARTRIDGE

(4)

PVDF BALL

CHECK

CARTRIDGE

(4)

MANIFOLD

O-RINGS

(4)

PTFE

00-1044-55

00-9189-55

00-9188-55

Sanifl ex™

00-1074-56

Wil-Flex™

00-1044-58

00-9189-58

00-9188-58

38-1371-58

PTFE-Encapsulated FKM

38-1371-60

LW0356 Rev. F

P A R T S L I S T I N G

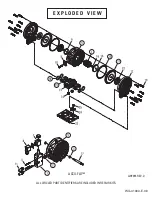

E X P L O D E D V I E W

D I S A S S E M B L Y / R E A S S E M B L Y

E L A S T O M E R O P T I O N S

D I M E N S I O N A L D R A W I N G

D I M E N S I O N A L D R A W I N G

D I M E N S I O N A L D R A W I N G

M A X I M U M T O R Q U E S P E C I F I C A T I O N S

Item

Description

Qty.

V2550

/PPPPE/…/P/N

A2550V

/PPPPA/…/P/N

V2550

/KKPPE/…/P/N

A2550V

/KKPPA/…/P/N

AIR DISTRIBUTION COMPONENTS

1

Air Valve Assembly

1

1

00-2044-99

00-2044-99

Air Valve Assembly, Solenoid

2

1

00-2014-99

00-2014-99

2

Gasket, Solenoid Valve

1

00-2640-56

00-2640-56

3

O-Ring, Shaft (-110, Ø.362" x Ø.103")

2

15-2650-49

15-2650-49

4

Screw, Hex Washer Head Torx, Solenoid Air

Valve (#4-24 x 1 1/4")

3

00-6134-03

00-6134-03

5

Center Section Assembly, Air Valve

3

1

00-3171-20

00-3171-20

Center Section Assembly, Accu-Flo

™4

1

00-3169-20

00-3169-20

6

Retaining Ring

1

00-2644-09

N/A

00-2644-09

N/A

7

Coil, 24V DC

1

00-2110-99-150

00-2110-99-150

Coil, 24V AC / 12V DC

1

00-2110-99-151

00-2110-99-151

Coil, 110V AC

1

00-2110-99-155

00-2110-99-155

8

Connector, Solenoid

1

00-2130-99

00-2130-99

9

Muffl er Element

1

00-3244-26

00-3244-26

10

Screw, Hex Washer Head Tri-Lobe (#10-14 x 1-1/4")

1

00-6114-03

00-6114-03

11

Muffl er, 1/4" MNPT

2

04-3240-07

04-3240-07

WETTED PATH COMPONENTS

12

Liquid Chamber

2

00-5014-20

00-5014-21

13

Manifold, Four Port, 1/4" (NPT)

1

00-5164-20

00-5164-21

14

Manifold Pipe Plug 1/4" (NPT)

2

00-7014-20

00-7014-21

10

Screw, Hex Washer Head Tri-Lobe (#10-14 x 1-1/4") 22

00-6114-03

BALL CHECK CARTRIDGE / MANIFOLD ORINGS

15

Ball Check Cartridge

4

*

*

16

Manifold O-Ring, TPE Fitted (-214, Ø.984 x Ø.139")

4

*

*

Manifold O-Ring, PTFE Fitted (-214, Ø.984 x Ø.139")

4

*

*

FULLSTROKE RUBBER / TPE / PTFE COMPONENTS

17

Shaft

1

00-3849-03

00-3849-03

18

Washer, Inner Piston (Ø.255" x Ø.468" x .060")

2

00-6844-03

19

Piston, Inner

2

00-3740-20

20

Diaphragm, Back-Up Seal PTFE only

2

*

21

Diaphragm, Primary

2

*

22

Piston, Outer

2

00-4640-20

00-4640-20

00-4640-21

00-4640-21

REMOVABLE FOOT COMPONENTS

23

Base, Removable Assembly

5

1

00-5540-99

24

Attachment Tab, Removable Base

1

00-5544-20

25

Screw, Slotted Hex Washer Head Tapping (#10-12 x 1/2") 1

00-6124-03

LW0356 Rev. F

ACCU-FLO™

W A R R A N T Y

22069 VAN BUREN STREET • GRAND TERRACE, CA 92313-5607

(909) 422-1700 • FAX (909) 783-3440

www.wildenpump.com

* See Elastomer Options

1

Air Valve Assembly includes item

6 and 9.

2

Accu-Flo™ Air Valve Assembly

includes items 2, 4, 7, 8 and 11.

ALL CIRCLED PART IDENTIFIERS ARE INCLUDED IN REPAIR KITS

DIMENSIONS

ITEM

METRIC

(mm)

STANDARD

(inch)

A

138

5.4

B

32

1.3

C

119

4.7

D

177

7.0

E

66

2.6

F

46

1.8

G

46

1.8

H

138

5.4

J

98

3.9

K

60

2.4

L

57

2.2

M

83

3.3

N

98

3.9

P

10

0.4

R

6

0.2

LW0351 REV. D

DIMENSIONS

ITEM

METRIC

(mm)

STANDARD

(inch)

A

138

5.4

B

34

1.3

C

60

2.4

D

99

3.9

E

125

4.9

F

145

5.7

G

148

5.8

H

76

3.0

J

11

0.4

K

103

4.1

L

172

6.8

M

98

3.9

N

60

2.4

P

57

2.2

R

83

3.3

S

98

3.9

T

10

0.4

U

6

0.2

LW0352 REV. C

VELOCITY MAXIMUM TORQUE SPECIFICATIONS

Description of Part

Torque

Liquid Chamber – Center Section (#10)

4.5 N•m (40 in-lb)

Outer Piston

5.6 N•m (50 in-lb)

Solenoid - Center Section (#4)

1.6 N•m (15 in-lb)

Tools Required:

•

5/16” Socket Wrench

•

7/16” Socket Wrench

•

Snap-Ring Pliers

CAUTION:

Before any maintenance or repair is attempted, the

compressed air line to the pump should be disconnected and all air

pressure allowed to bleed from the pump.

1.

Insert the smaller end of the air valve

assembly (item 1) into center section

(item 5) until fully seated. Install

retaining ring (item 6) in groove on air

valve assembly.

2.

Install backup O-rings (item 20) on to

surfaces of center section (item 5).

3.

Slide washer (item 18) and inner pistons

(item 19) on to ends of shaft.

4.

Slide diaphragms (item 21) on to ends

of shaft.

5.

Install outer pistons (item 22) on to ends

of shaft. Tighten to specifi ed torque (50

lb-in). Over-tightening could damage

outer piston.

6.

Install four (4) ball check cartridges

(item 15) into manifold (item 13). NOTE:

The cartridges must be installed in

correct orientation. Align grooves on

cartridge with ribs in manifold. Cartridge will be fl ush with end of the manifold if installed correctly.

7.

Install four (4) manifold O-rings (item 16) on to ends of manifold (item 13).

8.

Place upper screw boss in manifold (item 13) in-between the fl anges at the bottom of the center section

(item 5).

9.

Place the center section-manifold assembly between two liquid chambers (item 12), taking care to align

the large bore on liquid chamber over the diaphragm and the two (2) small bores over the manifold.

10.

Place in a vise and carefully press assembly together. Take care not to pinch or damage sealing O-rings.

There should be a consistent 0.05” gap between the center section (item 5) and liquid chambers (item

12).

11.

Fasten liquid chambers (item 12) to center section (item 5) and manifold (item 13) using (22) #10 screws

(item 10). Tighten fasteners to specifi ed torque (35 lb-in). Over-tightening fasteners could damage

center section.

12.

Press muffl er element (item 9) into muffl er cavity (near air inlet) of center section (item 5). Hold muffl er

element in place using one (1) #10 screw (item 10).

13.

There are two mounting options for the base assembly (item 23).

14.

Install one (1) NPT plug (item 14) into one (1) inlet port of the manifold (item 13). Install one (1) NPT plug

into one (1) discharge port on manifold.

LW0355 REV. D

ITEM METRIC

(mm)

STANDARD

(inch)

A

138

5.4

B

32

1.3

C

108

4.3

D

143

5.6

E

201

7.9

F

5

0.2

G

116

4.6

H

78

3.1

J

46

1.8

K

46

1.8

ITEM METRIC

(mm)

STANDARD

(inch)

L

99

3.9

M

127

5.0

N

196

7.7

P

98

3.9

R

60

2.4

S

57

2.2

T

83

3.3

U

98

3.9

V

10

0.4

W

6

0.2

LW0353 REV. D

DIMENSIONS

3

Air Valve Center Section Assembly includes items

1, 6, 9 and 10.

4

Accu-Flo™ Center Section Assembly includes

items 1, 2, 3, 4, 7, 8, 11 and 17.

5

Removable Base Assembly includes items 24 and 25.

Each and every product manufactured by Wilden Pump & Engineering, LLC is built

to meet the highest standards of quality. Every pump is functionally tested to insure

integrity of operation. Wilden Pump & Engineering, LLC warrants that pumps,

accessories and parts manufactured or supplied by it to be free from defects in

material and workmanship for a period of fi ve (5) years from date of installation or

six (6) years from date of manufacture, whichever comes first. Failure due to normal

wear, misapplication, or abuse is, of course, excluded from this warranty. Since

the use of Wilden pumps and parts is beyond our control, we cannot guarantee

the suitability of any pump or part for a particular application and Wilden Pump

& Engineering, LLC shall not be liable for any consequential damage or expense

arising from the use or misuse of its products on any application. Responsibility

is limited solely to replacement or repair of defective Wilden Pump & Engineering,

LLC. All decisions as to the cause of failure are the sole determination of Wilden

Pump & Engineering, LLC. Prior approval must be obtained from Wilden for

return of any items for warranty consideration and must be accompanied by the

appropriate MSDS for the product(s) involved. A Return Goods Tag, obtained from

an authorized Wilden distributor, must be included with the items which must be

shipped freight prepaid. The foregoing warranty is exclusive and in lieu of all other

warranties expressed or implied (whether written or oral) including all implied

warranties of merchantability and fitness for any particular purpose. No distributor

or other person is authorized to assume any liability or obligation for Wilden Pump

& Engineering, LLC other than expressly provided herein.

All boldface

items are

primary wear

parts

.

WIL-41000-E-06

WIL-41000-E-06

WIL-41000-E-06

WIL-41000-E-06

WIL-41000-E-06

WIL-41000-E-06

WIL-41000-E-06

WIL-41000-E-06