AAM

−

136

Revised June 5, 2012

26

POSSIBLE REMEDIES

PROBABLE CAUSES

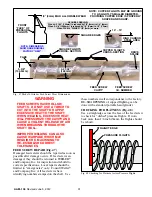

7. d. Feed screw / head spacing is incorrect.

7. d. With feed screw in grinder, but without

excluder seal on, measure the distance from

the face of the feed screw to the end of the

head, while pushing in with hand. It should

be

5/8”

(15.8mm). Make adjustment by

adding or removing spacer washers at drive

end.

8.

Mis

−

application. Grinder is not being used

for which it was designed.

Consult Weiler

r

and Company, Inc.

9.

An accumulation of bone chips or gristle on

inside of plate surface will impede product

flow and destroy definition.

Disassemble grinder and clean out all

material behind plate. Check cutting parts

for sharpness. Assemble parts correctly and

tighten ring. A bone/gristle collector may be

required.

10. Loose belts on drive system, sometimes

recognized by squealing.

10. Check belts after first 40 hours of running,

on new unit. Check belts for proper tension

and condition, at least every 6 months.

Belts should be tight enough to resist

slipping under maximum load.

SMEARED PRODUCT

PROBABLE CAUSES

POSSIBLE REMEDIES

1.

All or any of the previous mentioned causes

can cause product smear.

Re

−

read solutions to

LOW OUTPUT.

If

required, change pin and bushing. Sharpen

plate and correctly assemble the grinder.

RAGGED, DISCOLORED APPEARANCE

PROBABLE CAUSES

POSSIBLE REMEDIES

1.

All or any of the previous mentioned causes

can create this problem. Poor cutting action

produces ragged appearance. Dis

−

colored

product is due to a worn pin/bushing.

Re

−

read solutions to

LOW OUTPUT.

If

required, change pin and bushing. Sharpen

plate and correctly assemble the grinder.

POOR PARTICLE DEFINITION

PROBABLE CAUSES

POSSIBLE REMEDIES

1.

Wrong feed screw configuration, RPM, hole

size in plate, plate blockage and all

LOW

OUTPUT

causes.

Re

−

read solutions to

LOW OUTPUT

. Switch

from a two

−

blade to a four

−

blade

knifeholder, RPM increase, different feed

screw or plate hole size. Consult Weiler

r

and Company, Inc.