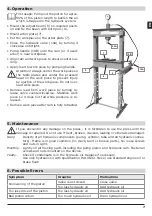

4. Operation

First usage: Pump out the piston for aprox.

50% of the piston length to banish the air

which is trapped in the hydraulic system.

• Mount the adjust beam (8) on required positi-

on and fix the beam with both pins (9).

• Mount arbor plate (7).

• Put the workpiece on the arbor plate (7).

• Close the hydraulic valve (19A) by turning it

clockwise until tight.

• Pump handle (19B) until the ram (or if used:

arbor) is near workpiece.

• Align ram and work piece to ensure center loa-

ding.

• Apply load to work piece by pumping handle.

Attention! Always center the work piece on

the table plates and center the pressure

head on the work piece to prevent injury

by ejection of the work piece. Do not over-

load work piece.

• Remove load from work piece by turning re-

lease valve counterclockwise. Stabilize work

piece so it does not fall while pressure is re-

leased.

• Remove work piece after ram is fully retracted.

5. Maintenance

If you encounter any damage on the press - it is forbidden to use the press until the

damage is repaired. Do not use if bent, broken, cracked, leaking or otherwise damaged.

Daily:

Density of all hydraulic components (pump, cylinder, tube and all hydraulic connec-

tors), Frame is in good condition (no crack, bent or broken parts), No loose screws

and nuts in sight.

Monthly: Lightly oil all moving parts including the pump piston and hydraulic ram. Fasten all

screws and nuts mounted on the device.

Yearly:

Check if condensate is in the hydraulic oil. Replace if necessary.

Use only hydraulic oil with specification ISO VG32. Never use standard engine oil or

brake fluid!

6. Possible Errors

Symptom

Ursache

Maßnahme

No lowering of the piston

Valve is not closed

Close valve

Too less hydraulic oil

Add hydraulic oil

Too less drive of the piston

Too less hydraulic oil

Add hydraulic oil

Bad piston return

Too much hydraulic oil

Drain hydraulic oil

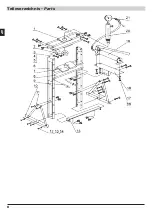

19A

19B

7

8

9

9

20A

7

EN