2

Check scope of delivery of the product when buying! After buying, the

manufacturer will not accept claims related to incomplete scope of delivery.

3.

SCOPE OF DELIVERY

4.

DESIGN AND PRINCIPLE OF OPERATION

Promix-SM323 lock is produced in a normally closed design, i.e., it is in the closed state when

de-energized and opens when supply voltage is applied.

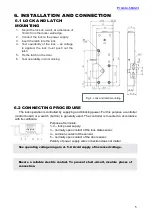

The lock is mounted on inner surfaces of the locker transversely to the door and is operable in

both vertical and horizontal positions. The counterpart (latch) is mounted on the door.

As the door is closed, the latch is inserted in the lock and becomes blocked therein. As supply

voltage is applied, the lock deblocks the latch and pushes it with a built-in pusher, which allows to

eliminate mounting of a handle on the door.

The spring-loaded pusher of the lock is connected to the lock state sensor.

Depending on modification, the lock is equipped with a door position sensor. The sensor is

made in the form of a movable stem connected to dry contact.

5.

TECHNICAL DATA

5.1 OPERATING CONDITIONS

The lock operation environment must be explosion-safe, free of current-conducting dust or

gases that cause metal corrosion and destroying insulation of current conductors and electric

elements, free of current-carrying dust or water vapor, and preventing ingress of water, steam,

fuel and lubricants.

Climatic conditions of operation

– У3.1 as per GOST 15150-69 with extended temperature

range:

Ambient temperature: -30 to +50

°С;

Relative air humidity: not higher than 98 % at 25

°С or lower temperatures without moisture

condensation and hoar-frost formation;

Installation indoors or outdoors excluding ingress of moisture, dust, dirt, etc. inside the lock.

1

–

Promix-SM323

lock

1 pc.

2

–

Promix-AD.DB.21 latch

1 pc.

3

– Self-tapping screw 3.5x30 (with

pressing disk)

4 pcs.

4

– Washer М4 (enlarged)

2 pcs.

5

– Self-tapping screw 4.2х14 (cup head)

2 pcs.

6

– Operation Manual

1 pc.

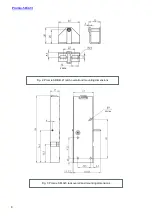

Fig. 1. Promix-SM323 scope of delivery