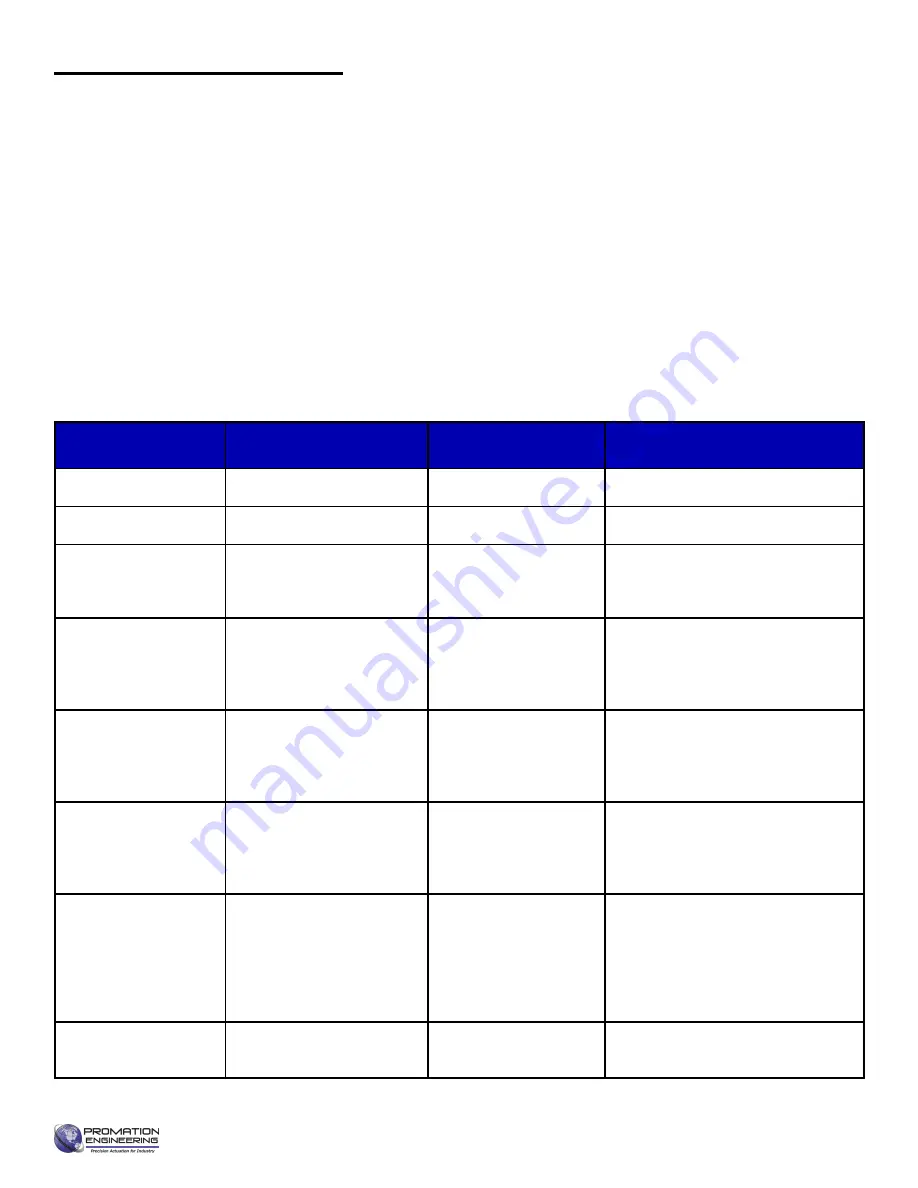

Condition

Control Card

Indicator

Status

Description

Power On (DIP 5 on)

Yellow LED On Steady

Normal Operation

Board has power

Power On (DIP 5 on)

Blue LED Blinking at 1 Hz

Normal Operation

Control Signal received at terminal

Power On (DIP 5 on)

Blue LED Flashes 3 times

rapidly followed by a one

second pause

Invalid Control

Signal

No or Low Control signal.

Check incoming control signal.

Power On (DIP 5 on)

Blue LED Flashes 3 times

rapidly followed by a one

second pause AND

Orange LED On

Invalid Control

Signal

Control (4-20mA) input wires

reversed (minimum 12mA signal

needed). Reverse Control Leads.

Power On (DIP 5 on)

No Motor Movement

Blue LED Flashes 4 times

rapidly followed by a one

second pause

Motor Stall

Feedback Potentiometer does not

sense movement. Check for Motor

problem. Inspect for loose gears,

potentiometer, wiring, etc

Power On (DIP 5 on)

Blue LED Flashes 5 times

rapidly followed by a one

second pause

Potentiometer Fault

Incorrect potentiometer adjustment

prior to running AutoCalibration.

Adjust Feedback Potentiometer

values to be in range.

Power On (DIP 5 on)

Blue LED Flashes 5 times

rapidly followed by a one

second pause

Travel Fault

Potentiometer Fault during

Calibrate Feedback step of

AutoCalibration. Adjustments to

End of Travel cams have set the

rotation for >90° travel. Reset to

90° travel and AutoCalibrate.

Power On (DIP 5 on)

No Motor Movement

Red or Green Motor

Direction LEDs Flash

Low Power

Incoming Power too low

The actuators are tested, calibrated and shipped in the Full CW position in the Direct Acting mode (CW is 4mA, CCW is

20mA). End of Travel cams are set at 90 degrees from each other.

A. Set the control device (valve or damper) to the closed position.

B. Mount the actuator to the device to be controlled (valve or damper).

C. Insure that the CW End of Travel cam trips the CW End of Travel switch at the correct CW point.

C.1. If the switch does not change state at the correct CW position, adjust Cam #2 per instructions on page 7.

D. Manually move (see Manual Override on page 8) the actuator so the valve or damper is in the fully CCW position. This

must be ≤ 90° of the full CW position.

E. Insure that the CCW End of Travel cam trips the CCW End of Travel switch at the correct CCW point.

E.1. If the switch does not change state at the correct CCW position, adjust Cam #1 per instructions on page 7.

If the End of Travel cams are adjusted at all, the actuator must be recalibrated.

F. Test actuator and device with a control input signal to insure that control signal corresponds to correct actuator and

device position.

Check End of Travel Settings

FM14_P1A

L

V VN4 V

er J 101614

Page 6 of 14 P1.A LV AdVanced Proportional Series

Check End of Travel Settings