15

10.3

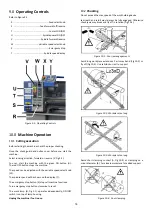

Cutting Tool Setup

The cutting angle is correct when the cutting edge is in line

with the centre axis of the work piece. Use the point of the

tailstock centre as a gauge and shims under the tool to obtain

the correct centre height (Fig 10‐5).

Figure 10‐5: Cutting tool setup

Use a minimum of two screws to clamp the cutting tool.

Avoid large tool extensions.

10.4 Recommended spindle speeds

ATTENTION:

Generally speaking, the smaller the cut diameter, the greater the

RPM required. Soft materials require higher speeds; hard metals

slower speeds.

Metal is usually machined with coolant or cutting oil applied.

Recommended speeds for cutting 10mm diameter, with HSS

tools (High speed steel tools):

Plastic: .............................................................. 2500 RPM

Aluminium: ....................................................... 2500 RPM

Brass: ................................................................ 1000 RPM

Cast iron: .......................................................... 1000 RPM

Mild steel: ........................................................... 800 RPM

High carbon steel: .............................................. 600 RPM

Stainless steel: .................................................... 300 RPM

For carbide tools (HM), 5 times higher speeds can be chosen.

For example:

Turning mild steel at a diameter of 20mm allows

With HSS tool ...................................................... 400 RPM

With carbide tool. ............................................. 2000 RPM

10.5

Manual turning

Apron travel (Z, Fig 10‐6), cross travel (AA) and top slide travel

(BB) can be operated for longitudinal and cross feeding.

Figure 10‐6: Machine controls

The correct feed depends on the material to be cut, the cutting

operation, the type of tool, the rigidity of the work piece

chucking, the depth of cut and the desired surface quality.

10.6

Turning with auto feed

Move the half‐nut lever (CC, Fig 10‐6) down, to engage the

automatic longitudinal feed. Move it up to disengage

Three feed rates are readily available by rotating the feed

select knob (R, Fig 9‐1).

For example:

Operation

feed/rev

select knob

Stock removal

0,28mm ................................

III

Finishing cut

0.14mm .................................

II

Micro finishing cut

0.07mm ..................................

I

NOTE:

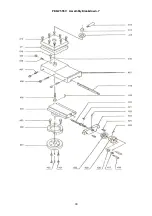

Three additional feed rates are available with different

change gear setup (Fig 10‐7).

Figure 10‐7: Available feed rates

The correct feed depends on the material to be cut, the cutting

operation, the type of tool, the rigidity of the work piece

chucking, the depth of cut and the desired surface quality.

When roughing big diameters reduce the depth of cut !

Summary of Contents for PBD-2555V

Page 18: ...18 15 0 Replacement Parts PBD 2555V Assembly Breakdown 1...

Page 20: ...20 PBD 2555V Assembly Breakdown 2...

Page 22: ...22 PBD 2555V Assembly Breakdown 3...

Page 24: ...24 PBD 2555V Assembly Breakdown 4...

Page 26: ...26 PBD 2555V Assembly Breakdown 5...

Page 28: ...28 PBD 2555V Assembly Breakdown 6...

Page 30: ...30 PBD 2555V Assembly Breakdown 7...

Page 32: ...32 PBD 2555V Assembly Breakdown 8...

Page 34: ...34 16 0 Wiring Diagrams PBD 2555V 1 230V PE 50Hz...