16

10.7

Thread cutting

Threading is performed in multiple passes with a threading

tool.

Each depth of cut should be about 0,2mm and become less for

the finishing passes.

A) To cut inch and metric threads

Set the machine up for the desired threading pitch (see

chapter 8.2).

Select the lowest possible spindle speed.

Engage the halve nut (V, Fig 10‐6).

NOTE:

The halve nut must stay engaged during the entire

threading process.

‐ Set the tool up for the threading pass.

‐ Start the motor.

‐ When the tool approaches the end of cut, stop the motor and

at the same time back the tool out, so that it clears the thread

diameter.

‐ Start the motor in reverse direction, let the cutting tool travel

back to the starting point.

Repeat these steps until you have obtained the desired results.

B) To cut metric threads with pitch

0,25/ 0,4/ 0,5/ 1,0/ 2,0 mm:

The halve nut can be opened at the end of cut, rather than the

motor being stopped and reversed.

10.8

Drilling operation

Use a drill chuck with MT2 arbor (option) to clamp centre drills

and twisted drills in the tailstock (Fig 10‐8).

Figure 10‐8: Drilling operation

For recommended speeds refer to section 10.4

To eject the drill chuck, fully retract the tailstock quill.

11.0

User‐Maintenance

WARNING:

Before any intervention on the machine, disconnect it from

electrical supply, pull the mains plug. Failure to comply may

cause serious injury.

An important security factor is the cleaning of the machine, of

bed, carriage and slides, of the floor and the surrounding

places.

Loose objects could come into contact with the moving chuck

or workpiece, creating hazards.

Empty the chip tray regularly.

Replace the coolant regularly, follow manufacturer’s advice.

Check that bolts are tight and electrical cords are in good

condition. If an electrical cord is worn, cut, or damaged in any

way, have it replaced immediately.

Motor brushes:

The motor brushes are due to wear and need to be replaced

when shorter than 12mm.

Set of brushes: Article No. PBD1830V‐103B

11.1

Lubrication

Spindle bearings are pre‐lubricated and sealed, and require no

further lubrication.

Weekly apply oil:

DIN 51502 CG ISO VG 68

(e.g. BP Maccurat 68, Castrol Magna BD 68, Mobil Vectra 2)

1…oil balls on change gear hubs

2…oil bed ways lightly

3…oil tailstock quill over entire length

4…oil lead screw on entire length

5…oil ball on lead screw bracket

6…oil balls on top slide

7…oil balls on tailstock

8...oil balls on carriage

9...oil balls on apron

Monthly apply grease:

DIN 51807‐1 non slinging grease

(e.g. BP L2, Mobilgrease Special).

10…grease teeth of change gears

11…grease rack over entire length

Summary of Contents for PBD-1830V

Page 18: ...18 15 0 Replacement Parts PBD 1830V Assembly Breakdown 1...

Page 20: ...20 PBD 1830V Assembly Breakdown 2...

Page 22: ...22 PBD 1830V Assembly Breakdown 3...

Page 24: ...24 PBD 1830V Assembly Breakdown 4...

Page 26: ...26 PBD 1830V Assembly Breakdown 5...

Page 28: ...28...

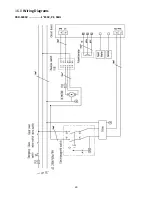

Page 29: ...29 16 0 Wiring Diagrams PBD 1830V 1 230V PE 50Hz...