14

9.0

Operating Controls

Refer to Figure 9‐1:

N ........................................... Spindle power ON/OFF

O .......................................... Spindle forward/reverse

P ...................................... Variable speed select knob

Q ...................................................... Emergency Stop

R ................................................ Spindle speed display

Figure 9‐1: Operating Controls

10.0

Machine Operation

10.1

Cutting execution

Before starting the machine check the proper chucking.

Close the chuck guard and pulley cover before you start the

machine.

Select running direction, forward or reverse (O, Fig 9‐1).

You can start the machine with the green ON‐button (N).

The red OFF‐button stops the machine.

The speed can be adjusted with the variable speed select knob

(P).

The spindle speed will be shown on the display (R).

The emergency stop button (Q) stops all machine functions.

Turn emergency stop button clockwise to reset.

Unplug the machine if not in use !

10.2

Chucking

Do not exceed the max speed of the work holding device.

Jaw teeth and scroll must always be fully engaged. Otherwise

chuck jaws may break and fly off in rotation (Fig 10‐1).

Figure 10‐1: Poor jaw engagements

Avoid long workpiece extensions. Parts may bend (Fig 10‐2) or

fly off (Fig 10‐3). Use tailstock or rest to support.

Figure 10‐2: Workpiece too long

Figure 10‐3: Workpiece too long

Avoid short clamping contact (A, Fig 10‐4) or clamping on a

minor diameter (B). Face locate workpiece for added support

Figure 10‐4: Poor clamping

Summary of Contents for PBD-1830V

Page 18: ...18 15 0 Replacement Parts PBD 1830V Assembly Breakdown 1...

Page 20: ...20 PBD 1830V Assembly Breakdown 2...

Page 22: ...22 PBD 1830V Assembly Breakdown 3...

Page 24: ...24 PBD 1830V Assembly Breakdown 4...

Page 26: ...26 PBD 1830V Assembly Breakdown 5...

Page 28: ...28...

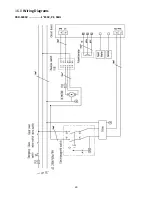

Page 29: ...29 16 0 Wiring Diagrams PBD 1830V 1 230V PE 50Hz...