-2- DP2000-1725-7/04

prepaid and only when the product, upon

examination, has proven to be defective.

This warranty does not apply to any

machine that has been subjected to

misuse, negligence or accident.

Proluxe

shall not be liable for the

injury, loss or damage, direct or

consequential, arising out of the use or

the inability to use the product.

No claim of any kind shall be greater in

amount than the sale price of the product

or part to which claim is made.

This is the sole warranty given by the company, it is in

lieu of any other warranties, expressed or implied, in

law or in fact, including the warranties of

merchantability and fitness for a particular use, and is

accepted such by the purchaser in taking delivery of

this product.

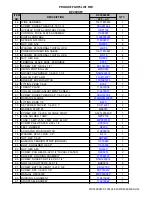

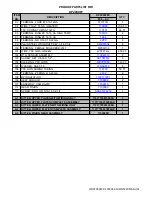

Specifications

Electrical:

2

08

V/50-60Hz/

4600

W/

22

.

11

Amps

Requires 30 AMP outlet

Includes 72” NEMA 6-

30

P approved

cord and plug.

Shipping Weight:

180lbs. (82kg)

Familiarize yourself with controls and

operating mechanisms before attempting

to use the DP2000. These are as

follows:

(A)

Pull Pressing Handle for raising

and lowering the upper platen.

This action forces the mating of

the platens.

(B)

Thickness Control Dial.

(C)

On/Off Button. The green light

above the button will illuminate

when turned on to indicate

power is in the press.

(D)

Control Panel

(see Control

Board Operations)

(E)

Handle for swing-out platen.

(F)

Upper platen

(G)

Lower platen

(H)

Handle adjustments

(see

Tightening the Pull-Down

Handle)

Safety Summary

Summary of Contents for DP2000FPE

Page 16: ......