5

2

4 - MAINTENANCE

Before any intervention on the compressor:

- Disconnect electrical cable.

- Empty the tank.

- Let cool the compressor.

A regular maintenance ensures working

without problem and increases the longevity

of the compressor.

FOR HANDLING: do not carry the compressor,

use the wheels (not the handles).

See table of the programmed maintenance(page 3)

Purge condensates: Advised after each use:

Purge to avoid the corrosion of the tank, .see (fig. 3).

These condensates contain oil , so you must recover

the condensates in a suitable container not to reject

into the sewers.

Clean or change the air filter: To guarantee the flow

of the compressor.( Fig. 7)

controls checking: By the tank pressure gauge,

check maximum value of the compressor.

Electric connector blocks checking: Tighten

correctly electric wires to have a good engine power.

3 - FOR YOUR SECURITY

The air delivered by your compressor allows you

to use many tools, follow conditions, advice and in

certain cases RESTRICTIONS OF USE for air tools

using compressed air.

Avoid any degradation of the electric cable and

move away from heat sources higher than 70°C.

At the end of work, unplug the cable and roll up it

around the handle of the compressor.

Do not use the compressor with bare or wet feet.

Do not to touch the compressor with wet hands.

Do not pull the cord to move the compressor or

to remove the plug.

Do not allow children to use the compressor.

Do not leave the compressor without monitoring

when it is connected; it can become source of

dangers.

Never introduce objects into the protection of the

transmission system.

- AFTER USING:

Never stop by disconnecting the electrical cable.

Never leave the compressor power connected

under pressure.

Switch the interruptor in "Off" position . (Fig. 2)

Empty the tank

Drain the tank (Fig.3)

Disconnect the electrical cable.

Ordinary maintenance does not require

specialized personnel.

The servicing of the group of compression as

well as other more complex bodies, must be

carried out by specialized personnel: Call for your

retailer.

The compressor does not start:

No electrical supply.

The compressor is already in pressure, empty

the tank.

The pressure switch is defective.

The compressor starts with difficulty, and

thermal protection sometimes operates:

The electric tension is insufficient. (210V

Minimum).

Electrical supply cord is too long, or wire section

too small. (electric cable coil)

Engine overload by cold weather.

Electrical supply cord is cut or disconnected.

You stopped your compressor by disconnecting

the cable and decompression did not take place.

Decompression defect, the tank is full, the

decompression did not take place.

(Check: Correct restarting with empty tank).

High resistance of the group: after removing air

filter, pour 4 to 5 drops of engine lubricating oil at

the air entry of the compressor and make the

compressor working during one minute, in order to

deposit an oil film in the mechanism.

Thermal protection is out of order, needs to be

regulated or changed according to the type.

Abnormal noises, vibrations:

Loosened or worned parts.

Worn group (mechanical noises).

Bad chocking of the compressor.

Tension of the belt to be checked.

Air leakage in the pneumatic circuit.

Opening of the safety valve:

Bad adjustment of the pressure controller, you

need to check that pressure gauge A ( Fig. 4) does

not exceed the pressure indicated on the identifica-

tion plate, this must be regulated by a specialist.

The safety valve is badly regulated or is

defective, to be replaced by an approved

equivalent model.

5 - FAULTS / SOLUTIONS

Air leaking from the valve of air pressure switch :

- defective valve of the pressure switch, change it.

No return valve blocked by an impurity or worn,

clean or change the no return valve or the internal

rubber valve with its spring. ( Fig. 9)

Low flow rate, pressure does not increase:

air filter is dirty, you must clean it.(Fig. 7)

air pressured is leaking by the connections, check

the connections.

Cylinder valves are broken or valve seat gasket

torn, you must check the pump.

Excessive consumption by the segmentation,

gasket leakages, you must check the pump.

Impossible adjustment of the output air pressure:

The internal diaphragm of the pressure reducer is

torn (fig.4) replace it.

Please follow the advice below for the mainte-

nance of your compressor:

FAULTS / SOLUTIONS

COMMUNICATION- TRACKING PRODUCT

SECURITY

MAINTENANCE

To use your compressor correctly, only use it

intermittently, i.e. 60% of use for 40% of downtime.

Beyond this limit, the engine risks overheating

problems.

- PRECAUTIONS TO PAINT:

If the electric motor and the interior of the pump are

dirty, your compressor life expectancy will be

reduced:

In order to avoid this problem, only move away

the compressor by lengthening the tube of your tool.

The electric safety of this machine is assured only

when it is correctly connected with an efficient

grounding connection , as recommended in the rules

of electric safety requirements.

The responsibility for the manufacturer will not be

committed if grounding connection of the installation

is incorrect.

To avoid burns, during the work and a few minutes

after working, never touch the pipes of connection of

the cylinder head, the non-return valve nor the parts

of the compressor subjected to heating.

- OPERATING TIME:

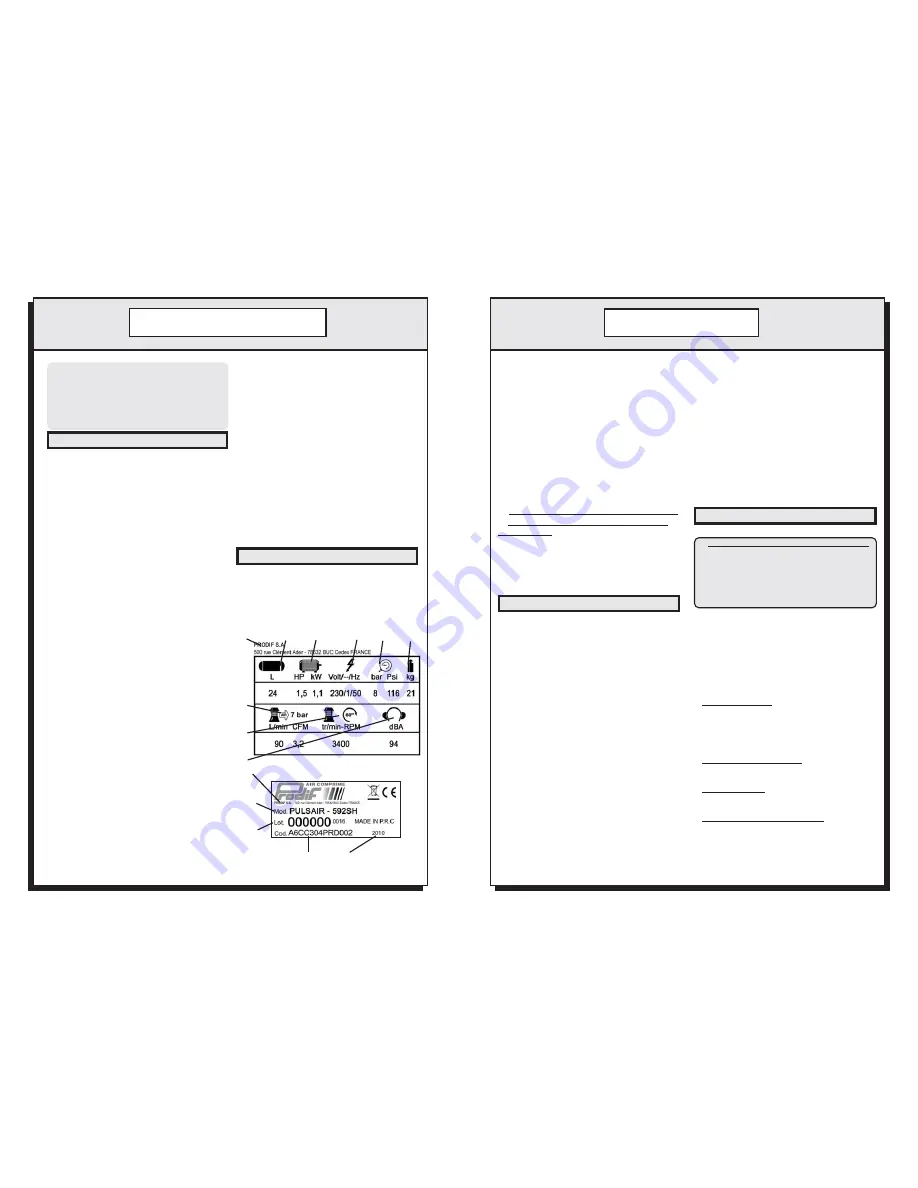

For any communication with the distributor, please

indicate the identification sticker data of the

product [fig.1] The sticker is applied on the side of

the compressor.

IDENTIFICATION STICKER OF THE PRODUCT

[fig.1]

6 - COMMUNICATION- TRACKING PRODUCT

1 2 3 4 5 6

7

8

9

1

12

10

11 13