22

Eng

lis

h

Installation

•

Flat mount

a) Installation positions of stud bolts or positions of boss molds when

attaching installation brackets at the top and bottom surfaces of the GP

unit

b) Installation positions of stud bolts or positions of boss molds when

attaching installation brackets on either side of the GP unit

d) 4-M4 x 10L stud bolts (no foreign material present on the base due to

sparking or similar phenomena) or boss molds

e) Center of the display area

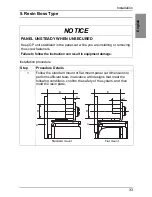

Note :

If you are designing the panel with a material other than sheet metal, ensure that

the material has sufficient strength.

A

B

C

R

A1

A2

Panel

Type

Resin

Boss

Type

PFXGP4301

TADR

143 mm (+0.5, -0 mm) (5.63 in [+0.02, -0 in])

109 mm

(+0.5, -0 mm)

(4.29 in

[+0.02, -0 in])

1.6 mm

(0.06 in)

SPCC

(JIS G

3141) or

SECC(JIS

G 3313)

1.5 mm

(0.06 in)

SUS304

(JIS G

4305)

2 mm

(0.08 in)

maximum

1 mm

(0.04 in)

maximum

70.5 mm

(+0.25, -0 mm)

(2.78 in [+0.01, -0 in])

72.5 mm

(+0.25, -0 mm)

(2.85 in [+0.01, -0 in])

PFXGP4401

TADR

174.5 mm (+0.5, -0 mm) (6.87 in [+0.02, -0 in])

134.2 mm

(+0.5, -0 mm)

(5.28 in

[+0.02, -0 in])

86.3 mm

(+0.25, -0 mm)

(3.4 in [+0.01, -0 in])

88.2 mm

(+0.25, -0 mm)

(3.47 in [+0.01, -0 in])

PFXGP4501

TADR

241 mm (+0.5, -0 mm) (9.49 in [+0.02, -0 in])

188 mm

(+0.5, -0 mm)

(7.4 in

[+0.02, -0 in])

119.2 mm

(+0.25, -0 mm)

(4.69 in [+0.01, -0 in])

121.8 mm

(+0.25, -0 mm)

(4.8 in [+0.01, -0 in])

PFXGP4601

TADR

289.4 mm (+0.5, -0 mm) (11.39 in[+0.02, -0 in])

214.4mm

(+0.5, -0mm)

(8.44in.

[+0.02, -0in.])

142.4 mm

(+0.25, -0 mm)

(5.61 in [+0.01, -0 in])

147 mm

(+0.25, -0 mm)

(5.79 in [+0.01, -0 in])

B

Y1

Y1

a

e

a

d

d

a

A

A1

A2

C

X1

X1

a

R

B

Y2

Y2

e

b

b

b

b

X2

X2

R

A

A1

A2

Rear panel (resin plate) surface

Rear panel (resin plate) surface