19 -

PRM 60

Fit drain and oil level plugs (26) with bonded washer (31) to the sides of the gearcase (2). Fit oil filling plug (48) with

bonded washer (54). Fit dipstick (28) and breather (30) with bonded washer (52). Finally adjust the gear selector lever

(44) into the required position.

9.7.6 Cone Clutch Selection

With the selector lever (44) in neutral position manually rotate the output coupling (23). The eccentricity of the cone

clutch (11) groove causes an axial shift on the selector shoe (22). The variable distance between the end of the selector

shoe (22) and the output shaft (14) vertical centre line upon rotation provides MAX & MIN axial movement of the

selector shoe (22). With no further rotation of the output coupling (23), screw the dog point grub screw (50) until contact

is made with the bottom of the selector shoe (22). Fit the nut (49) upto selector body (18),

not

allowing any rotation of

the dog point grub screw (50). Unscrew the dog point grub screw (50) simultaneously with the nut (49) attached until a

0.60mm gap is achieved between the nut (49) and the selector body (18). With no further movement of the dog point

grub screw (50) tighten the nut (49) against the selector body (18) to 17 Nm (13lbft). This will give 0.60mm clearance

between the bottom of the selector shoe (22) and the dog point grub screw (50) at max cone eccentricity.

CAUTION:

This condition can only be maintained with the clutch at the top dead centre. If this is not

achieved the gear selection will be affected, creating difficulty in gear engagement or disengagement.

10. SPECIAL TOOLS

Oil seal to selector housing

PR29418

Oil seal to gearcase

PR29281

Oil seal to front cover

PR29283

10.1 Tool Kit

Socket size

13mm

24mm

30mm

Drain Plug

13mm A/F

10.2 Tightening torques

RECOMMENDED TIGHTENING TORQUES

Size

Grade

Type

Nm

M6

8.8

Bolt

12

M8

8.8

Nut

24

M8

8.8

Screw

30

M16

8.8

Binx Nut

56

M16

8.8

Special Nut

170

*

M25

8.8

Locknut

135

*NOTE: USE LOCTITE 243 ON THREADS AND STAKE NUT INTO KEYWAY.

11. REPLACEMENT PARTS ORDERING

When ordering replacement parts the following should be quoted:

a) Gearbox model and serial number

b) Description(s) and part number(s) of the component(s) required

c) Quantity required

d) Orders and enquiries for replacement parts must be made through PRM Newage distributor/dealer network

NOTE:

Enquiries relating to a technical or service nature can be made direct to:

PRM NEWAGE LTD.

BARLOW ROAD

COVENTRY CV2 2LD

ENGLAND

TEL: +44 (0)24 7661 7141

Summary of Contents for PRM 60

Page 1: ...PRM 60 WORKSHOP MANUAL...

Page 2: ......

Page 11: ...9 PRM 60 BASIC INSTALLATION DETAILS PRM 60 Figure 4 Intallation Details...

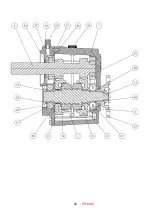

Page 23: ...21 PRM 60 13 Exploded view and Cross section Figure 5 Exploded view and cross section...

Page 24: ...22 PRM 60...

Page 25: ...23 PRM 60...

Page 26: ...24 PRM 60...

Page 28: ...26 PRM 60 NOTES...