15 -

PRM 60

8. FAULT FINDING

The following fault finding chart is designed to help diagnose some of the problems which might be encountered. It

assumes that the installation and operating instructions in this manual have been followed and we advise that these are

checked before proceeding to fault finding.

To avoid prejudicing warranty rights, no repair or other work should be done on the gearbox during the warranty without

first contacting PRM Newage Ltd. or an authorised distributor or dealer for advice.

FAULT FINDING CHART

SYMPTOM

CAUSE

REASON

REMEDY

No drive ahead or astern

Broken drive plate

Broken input shaft

Broken output shaft

Replace drive plate

Replace input shaft

Replace output shaft

Propeller speed does not

increase with engine speed,

ahead and astern

Remote control cable or

linkage not allowing F-N-R

lever to move correct

distance

Too much oil within gearbox

Remove cable and operate lever

by hand to check movement.

Adjust cable if necessary

Recheck oil level and adjust.

Propeller speed does not

increase with engine speed

in one direction only

Damaged clutch cones

Incorrect lever setting

Too much oil within gearbox

Remove and examine clutch

and replace if necessary

Reset lever to end stops

Recheck oil level and adjust.

Excessive noise from

gearbox at low speeds

Engine idle speed set too low

Torsional vibration

Faulty adjustment

Torsional incompatibility of

elements in driveline

Increase idling speed

If not cured by increasing engine

idling speed, refer to engine

supplier

Excessive noise throughout

operating range

Defective input coupling

Propeller shaft misalignment

Input coupling worn or

damaged

Hull flexing or faulty

installation

Remove, examine and replace if

necessary

Check the alignment of the

propeller shaft coupling; if

necessary rectify by adjusting

the shims under the engine

mounts or the engine mounts

themselves

Excessive vibration

throughout operating range

Propeller out of balance

Engine/gearbox

misalignment

Defective bearing

Propeller damaged or badly

machined

Faulty installation

Bearing worn or damaged

Remove the propeller and check

that the pitch, weight, diameter

and balance of all the blades are

equal and rectify if necessary

Remove the transmission and

check that the flywheel face is

flat and that the flexible input

coupling is aligned correctly

Isolate defective bearing,

remove and replace

Excessive oil temperature

Power too high

Oil level too high/low

Incorrect engine rating

Incorrect oil type

Re-assess engine power

Fill with correct oil

Fill to correct oil level on dipstick

Oil level needs constant

topping up

Oil leaks

Defective oil seal, sealant or

‘O’ ring

Clean the outside of the

gearcase, particularly around

the ends of shafts including the

output shaft. Run the engine

and inspect the gearbox for

leaks. Replace seals as required

Escape of high pressure from

gearbox when dipstick is

removed

Defective breather causing

leaks past oil seals

Contact distributor or factory for

advice

Difficulty in moving single

lever control

Faulty installation

Incorrect selector adjustment

Remote control operating

cable kinked or frayed

Re check adjustment see 9.7.6

for procedure

Check the installation and

eliminate all tight bends in the

cable

Warning:

Before carrying out any service work always ensure that the engine is switched off and

disconnect the operating cable from the gearbox.

Caution:

The above operations should be carried out by suitably qualified personnel and strictly in

accordance with the procedures detailed in the workshop manual

Summary of Contents for PRM 60

Page 1: ...PRM 60 WORKSHOP MANUAL...

Page 2: ......

Page 11: ...9 PRM 60 BASIC INSTALLATION DETAILS PRM 60 Figure 4 Intallation Details...

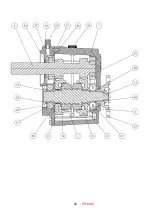

Page 23: ...21 PRM 60 13 Exploded view and Cross section Figure 5 Exploded view and cross section...

Page 24: ...22 PRM 60...

Page 25: ...23 PRM 60...

Page 26: ...24 PRM 60...

Page 28: ...26 PRM 60 NOTES...