4

PM-30MV v3 2020-10

Copyright © 2020 Quality Machine Tools, LLC

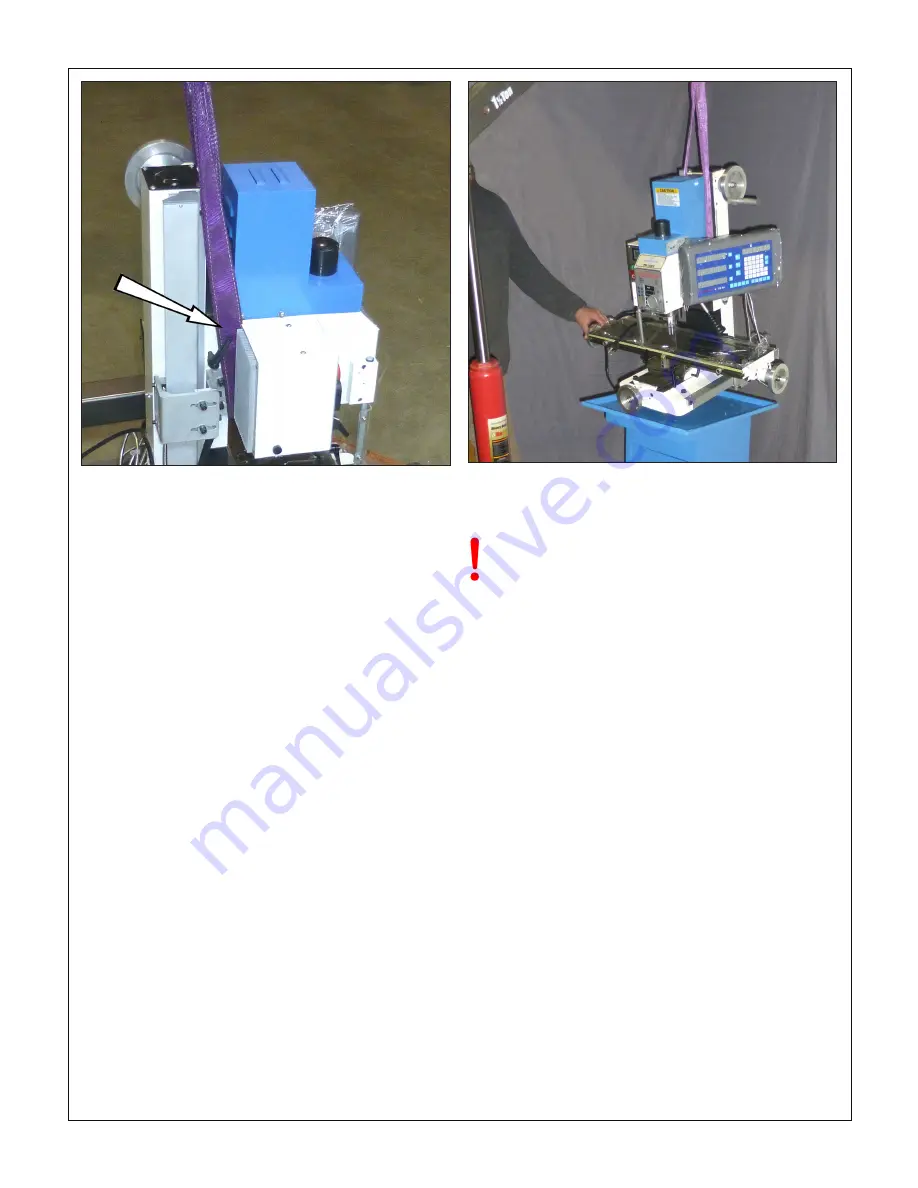

Figure 1-2

Sling position

Figure 1-3

Lowering the mill into position

Assembly and cleanup

Unfinished metal surfaces

may be protected in shipping by

thick grease and/or paper. Carefully remove these using a

plastic paint scraper, disposable rags and a light-oil such as

WD-40. Coat bright machined surfaces with a rust preventa-

tive such as Rustlick.

Level the mill using the table surface for reference, shimming

under the tray if necessary. Oil the ways and leadscrews (Z-ax-

is screw excepted, inaccessible).

Initial checks

Read Section 3 if unsure about any item in the following

1. Check that: A There is no chuck or collet is installed; B

There are no clamps or locks on moving parts, and; C The

speed control knob is at its

lowest setting

, fully count-

er-clockwise.

2. Remove the blue motor cover. Make sure the belt is set

for low speed (belt running on the larger spindle pulley.)

If not, re-position the belt, Figure 3-2. Replace the motor

cover.

3. Connect 220 Vac power.

4. Be sure the E-Stop (Emergency) button has not been

pushed in (it should pop out when twisted firmly clock

-

wise).

5. Press the Power button. The power lamp and the tach

display should light.

6. Check the emergency function by pressing the E-Stop

button. The power lamp should go out, de-energizing the

contactor circuit, disabling all electrics.

If this doesn’t

happen, the E-stop function is defective, and needs

attention.

7. Restore power by twisting the E-Stop button

firmly

to the

right; this will cause it to pop out.

8. Check that the chip guard switch disconnects power when

the guard is swung out.

DO NOT LEAVE THE MACHINE UNATTENDED

DURING THIS PROCEDURE

Test run procedure

1. Select Forward (F) spindle direction. The tachometer

should display between 50 and 100 rpm.

2. Rotate the speed potentiometer cw for a speed of about

200 rpm. Run the spindle at that speed for about 1 min-

ute, then progressively increase the speed to the max

(about 1500 rpm), pausing for about 1 minute at each

200 rpm increment.

3. Repeat step (2) with the spindle reversed (R).

4. Set the belt for high speed, then repeat steps (2) and (3).

The machine should now be ready for normal operations.