If the cleaner is left unattended remove the key from the

main power switch.

Do not leave the cleaner unattended particularly if children

are present. Do not use or install the cleaner in places

where flammable gases or liquids are present. Do not use

flammable liquids or chemicals with this cleaner. Ensure

that the instruction manual and warnings are always to hand

and are legible. Replace any torn or missing pages.

This machine must only be used on flat and level surfaces.

DO NOT USE IT ON INCLINED SURFACES

without the

assistance of the appropriate personnel.

Do not operate the machine in bare feet, with sandals or any

kind of open footwear.

Do not wet electrical components with water or any other

liquid. Dry the machine with a cloth.

Powr-Flite is not responsible for the disposal or production

of products necessary for its operation; e.g. batteries, deter-

gents, etc.; the customer himself must, therefore, arrange

for the disposal of sub-stances harmful to the environment

in accordance with the laws of the country in which it is

used.

The same precautions should be taken when the machine is

scrapped.

The machine generates a sound pressure level (noise) in

an industrial environment (warehouse/ shop floor) which

is less than 80 dBA and is therefore absolutely harmless

for the operator. However, in other surroundings, this level

may be exceeded in which case the customer must provide

appropriate protection (ear defenders) as well as notices to

promote their use and periodic hearing examinations.

The operator must not wear clothing with wide sleeves, laces

or belts; he must not approach the machine with bare or

wet feet; he must not pull out the plug by pulling the cable;

must not smoke if the environment or products used do not

allow it.

For lifting and transporting use only specialized personnel

(slingers, crane operators, etc..) with proper lifting gear

which is suitable for the weight of the various components.

- Transport (especially by road) must be carried out with

in the correct way and with the adequate means so as to

protect the components (especially the electronic ones)

from violent shocks, humidity, vibration, etc..; the machines

are supplied with wheels and therefore need to be securely

anchored before beginning transportation.

- 4 -

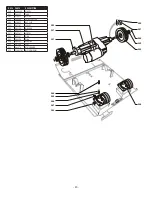

Diagram 2

Summary of Contents for PAS20DX

Page 12: ......

Page 15: ......

Page 16: ...A Tacony Company 3101 Wichita Court Ft Worth TX 76140 1755...