8

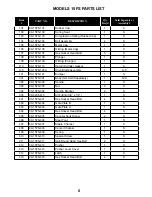

Assemblies, Kits & Accessories

ITEM # PART NO.

DESCRIPTION

QTY. REQ’D

A-2

09-445-29737

5/8” Adapter Pad

1

A-3

09-445-29738

3/4” Adapter Pad

1

A-4

09-445-29757A

6 Oz. Air Tool Oil

1

A-5

09-15FS-120A

DRIVE BLADE ASSEMBLY:

Whole assembly is necessary, individual parts not

sold separately.

1

A-6

06-99606

15FS POWER ROLLER CONVERSION KIT

1

A-7

09-50P3104A

9MM BEARINGS W/ MOLDED COVERS (SET

OF 2)

1

A-8

09-RB15FSA

COMPLETE ROLLER SET (4 LRG R 2

9MM ROLLER)

1

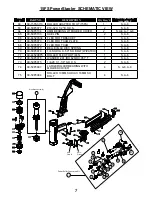

15FS PowerStapler Parts Continued... FLEX Foot operation

FLEX Power Roller Foot Adjustment:

Wood varies from one manufacturer to the

next. The different wood pro

fi

les may be due

to height and length of the

fl

ooring tongue and

whether or not there is a nail pocket.

First, loosen the two hex bolts under the FLEX

foot with the Allen Wrench supplied with the

stapler. (Figure 1.)

Next, set the stapler on a sample of your

fl

ooring.

Use the adjustment lever at the back of the

roller foot to raise or lower the stapler to the

wood.

Match the Adapter Foot triangle & 9mm rollers

so that they are pointing into the 90° angle

created by the tongue and the top of the wood

(see Figure 2).

For wood with a nail pocket, line up the triangle

& 9mm rollers so at the top of the nail pocket.

When the adjustment lever is in the correct

position for your wood sample, tighten the two

hex bolts to lock the FLEX foot into place.

Always check your adjustment with a sample to

ensure the nail is driving into the nail pocket.

Figure 2.

Hex Allen Wrench

FLEX Foot Adjustment Lever

1. Loosen 2 hex screws.

2. Raise or lower the FLEX Foot to your

wood sample.

3. Match the 9mm rollers to the nail pocket.

4. Tighten 2 hex screws.

5. Test wood sample with new adjustment.

Figure 1.

Adjust FLEX lever so the 9mm rollers

are above the

fl

ooring tongue