18

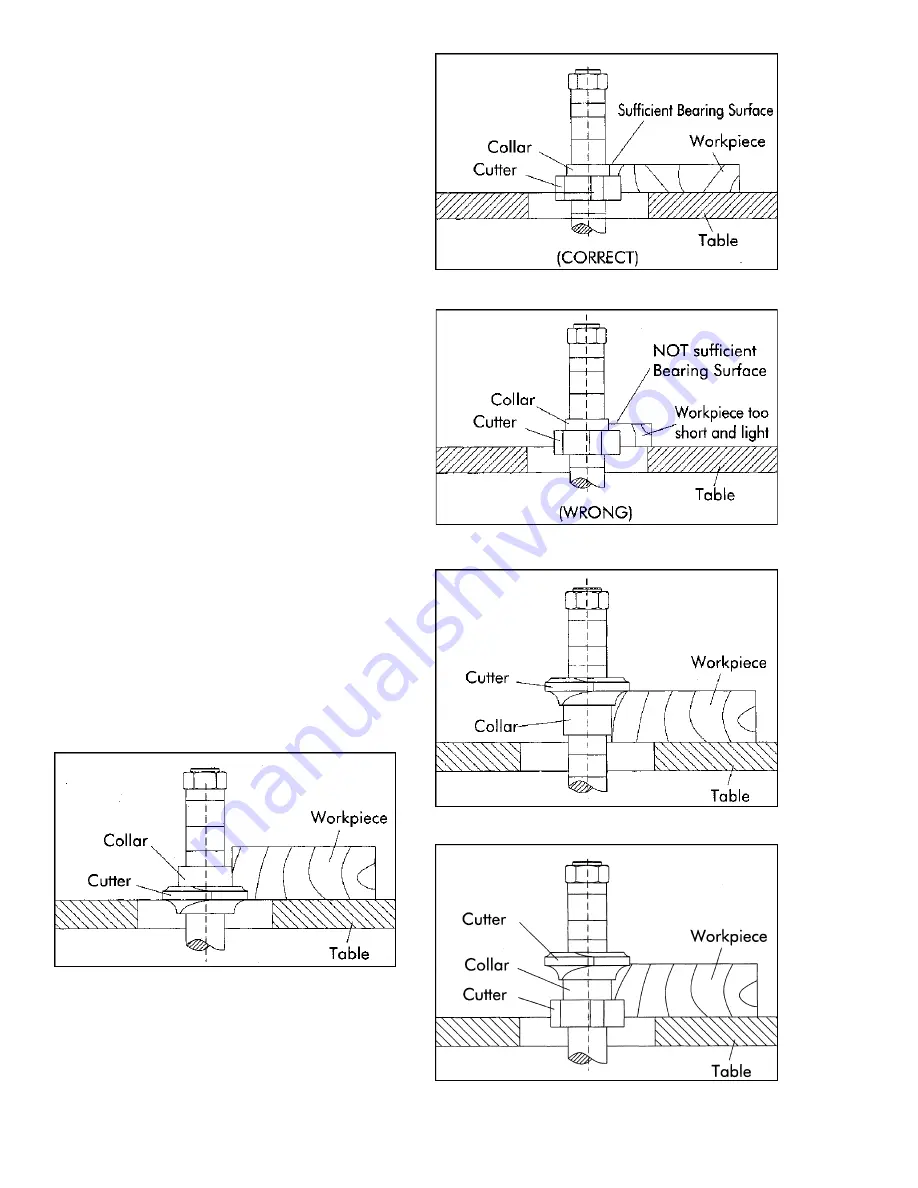

POSITION OF COLLARS

When shaping with collars, the collar must have suffi-

cient bearing surface, as shown in Figure 35. Also

the work must be fairly heavy relative to the cut being

made. Under no circumstances should a short, light

workpiece be shaped against the collars, as shown in

Figure 36.

The collars may be used in any of the following posi-

tions: above, below, or between the cutters.

1.

When the collar is used below the cutter, as shown

in Figure 37, the progress of the cut can be seen

throughout the operation. However, any accidental lift-

ing of the work will gouge the wood and ruin the

workpiece.

2.

When the collar is used above the cutter, as shown

in Figure 38, the cut can not be seen, but this method

offers an advantage in that the cut is not affected by

slight variations in the thickness of the stock. Also,

accidental lifting of the workpiece will not gouge the

workpiece; simply repeat the operation to correct the

mistake.

3.

Using the collar between two cutters has the

advantages and disadvantages of the first two proce-

dures, and is frequently used where both edges of the

work are to be molded. See Figure 39.

NOTE: It is advisable to place the cutter as low as

possible on the spindle to reduce spindle deflection

and ensure the best possible finish. Also make sure

that the contacting surfaces of the cutter are smooth,

sharp, clean and without dents.

FIGURE 35

FIGURE 36

FIGURE 37

FIGURE 39

FIGURE 38

Summary of Contents for TS29

Page 25: ...25 Fence Assembly TS29 Shaper ...

Page 27: ...27 Spindle Assembly TS29 Shaper ...

Page 29: ...29 Cabinet Assembly TS29 Shaper ...

Page 31: ...31 Sliding Table Assembly TS29 Shaper ...

Page 33: ...33 Speed Indicator TS29 Shaper ...

Page 35: ...35 Electrical Components TS29 Shaper ...

Page 38: ...38 Quill Assembly TS29 Shaper ...