17

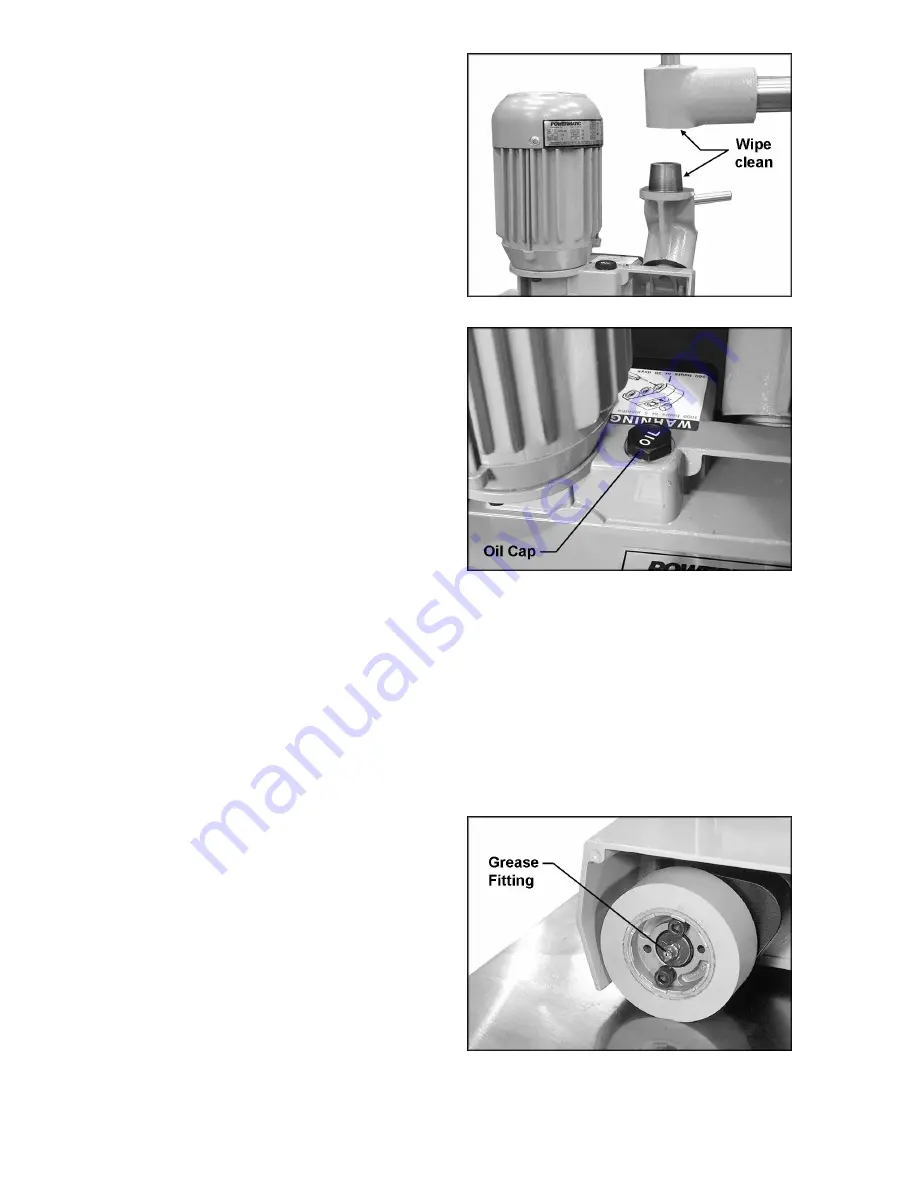

The mating parts of the arm cone and swivel

cone should be kept clean. See Figure 21.

When disassembling any of the cones from the

stock feeder, wipe off both mating parts with a

clean rag before re-assembling. NOTE: These

cones are subject to high torques and it may be

necessary to periodically re-tighten the lock

handles until the cone surfaces become

securely seated.

Lubrication

Gearbox

The Stock Feeder is shipped with oil installed in

the gearbox. Occasionally check the oil level

and add oil if necessary. The oil level should be

approximately 1-1/2” deep; that is, about 1” from

the rim of the hole. Completely drain and refill

the oil every 1,000 working hours, or every 6

months, with a good quality gear oil.

To change the oil:

1. Loosen the screw (A, Figure 5) which holds

the feeder body to the horizontal arm.

2. Carefully remove the feeder body from the

horizontal arm.

3. Unscrew and remove the oil cap (identified

in Figure 22) and turn the feeder body

upside down to completely drain the oil.

(NOTE: Always dispose of used oil

properly.)

4. Turn feeder body right side up, and pour

new oil into the fill hole, until it is about 1”

from the rim.

5. Re-install the oil cap (Figure 22).

Rollers

Each of the three rollers has a grease fitting

(Figure 23) located in the hub center. Use a

grease gun to insert a good quality, all-purpose

grease into these fittings every 200 working

hours, or every 30 days.

Figure 21

Figure 22

Figure 23

Summary of Contents for PF3-JR

Page 7: ...7 Features ...

Page 21: ...21 PF3 JR Stand Assembly ...

Page 23: ...23 PF3 JR Stock Feeder ...

Page 24: ...24 PF3 JR Electrical Connections ...

Page 25: ...25 Boring Template SCALE 1 1 Cut out and tape into place on mounting surface ...

Page 26: ...26 NOTES ...

Page 27: ...27 ...