13

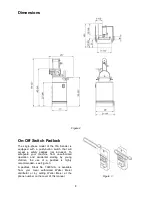

Dust Outlet and Cord Plate

Refer to Figure 12:

1. Install

the

dust outlet

using the four M6 x 12

pan head flanged screws

(FF).

2.

Single Phase model:

Feed the electrical

plug through the hole in the stand, and slide

the cord plate through also. Secure the cord

plate to the stand using the two M5x12

pan

head screws

(GG) as shown.

Switch

(Single Phase Model)

Refer to Figure 13:

1. Place the

push button switch

into the

rectangular opening from inside the stand.

2. Secure the switch to the outside of the

stand, using two M4x8

pan head screws

(HH), two M4

lock washers

(JJ) and two M4

flat washers

(KK).

Electrical Connections

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

The 31A Sander is equipped with either a

single

phase 115/230 volt

motor (pre-wired 115V); or

a

three phase 230/460 volt

motor (pre-wired

230V).

The

three phase

sander is not equipped with a

plug. You may either install a UL/CSA listed plug

suitable for 230 or 460 volt operation, or “hard-

wire” the sander directly to a service panel.

The

installer shall follow local regulations and

National Electrical Code, ANSI/NFPA 70

installation requirements.

If the Sander is to be

hard-wired to a panel, make sure a disconnect is

available for the operator. During hard-wiring of

the machine, make sure the fuses have bee n

removed or the breakers have been tripped in

the circuit to which the Sander will be

connected.

If connected to a circuit protected by fuses, use

time delay fuse marked “D”.

Make sure the voltage of your power supply

matches the specifications on the motor plate of

the sander.

Figure 12

Figure 13

(single phase model)

Converting from 115 Volt to 230 Volt

(Single Phase Only)

To convert from 115V to 230V (1 phase model),

consult the diagrams inside the cover of the

motor junction box, to determine how to switch

the motor leads. A similar diagram is also found

at the back of this manual.

The 115V attachment plug supplied with the

sander must be replaced with a UL/CSA listed

plug suitable for 230V operation. Contact your

local authorized Walter Meier service center or

qualified electrician for proper procedures to

install the plug. The sander must comply with all

local and national codes after the 230 volt plug

is installed.

Summary of Contents for 31A

Page 20: ...20 Guide to Sanding Belts and Discs ...

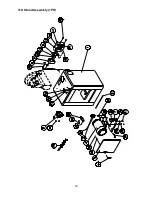

Page 23: ...23 31A Stand Assembly 1PH ...

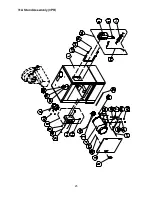

Page 25: ...25 31A Stand Assembly 3PH ...

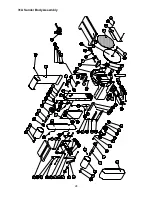

Page 28: ...28 31A Sander Body Assembly ...

Page 29: ...29 Electrical Connections 1 Phase ...

Page 31: ...31 ...