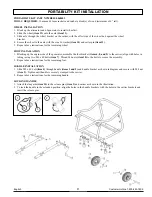

GENERATOR: Brushes

The brushes in the generator should be inspected once

every year for chips and cracks. Brushes should be replaced

when they are worn to 1/4 inch (7mm).

NOTE: Replace brushes in sets only, never separately.

Replace only with brushes specified in parts list. Other

brushes may appear to be identical but may have

completely different mechanical and electrical

characteristics.

INSPECTING THE BRUSHES:

1.

Remove 2 screws (V) and end cover (W).

2.

Remove screw (X) holding the brush module (Y).

3.

Disconnect the blue (+) and yellow (-) brush wires from

the tabs.

4.

Replace if worn to 1/4 inch (7mm).

5.

Do not over tighten screw.

HEAT SHIELD:

Inspect to ensure that all heat shields and heat deflectors

are intact and in place. Do not remove any parts or modify

parts. Removing or modifying parts could cause serious

damage to the unit.

ENGINE: Carburetor Icing

During the winter months, rare atmospheric conditions

may develop which will cause an icing condition in the

carburetor. If this develops, the engine may run rough, loose

power, and may stall. Call Product Service for more

information.

QUICK STARTING TIPS FOR UNITS THAT HAVE

BEEN SITTING FOR AWHILE:

If your unit has been sitting around for a long time period

and is hard to start, try doing some of these easy steps before

calling the Customer Hotline.

1.

Check the oil level.

2.

Replace the old fuel.

3.

Change the spark plug.

4.

Check the fuel lines. Make sure the fuel valve is open.

5.

Check all generator parts for integrity.

6.

Clean the Carburetor.

INFREQUENT SERVICE

If the unit is used infrequently, difficult starting may

result. To eliminate hard starting, follow these instructions:

1.

Run the generator at least 30 minutes every month.

2.

Run the generator, then close the fuel shut-off valve and

allow the unit to run until the engine stops.

3.

Move the engine switch to the “OFF” position.

LONG TERM STORAGE

When the generator set is not being operated or is being

stored more than one month, follow these instructions:

1.

Replenish engine oil to upper level.

2.

Run the generator, then close the fuel shut-off valve and

allow the unit to run until the engine stops.

3.

Move the engine switch to the “OFF” position.

4.

After the unit has cooled, drain gasoline from fuel tank,

fuel line and carburetor.

5.

Pour about one teaspoon of engine oil through the spark

plug hole, pull the recoil starter several times and replace

the plug. Then pull the starter until you feel the piston is

on its compression stroke and leave it in that position.

This closes both the intake and exhaust valves to prevent

the inside of the cylinder from rusting.

6.

Cover the unit and store in a clean, dry place that is well

ventilated away from open flame or sparks.

NOTE: We recommend always using a fuel stabilizer.

A fuel stabilizer will minimize the formulation of fuel gum

deposits during storage. The fuel stabilizer can be added

to the gasoline in the fuel tank, or into the gasoline in a

storage container.

12

Customer Hotline 1-800-445-1805

SER

SER

VICE

VICE

AND ST

AND ST

ORAGE

ORAGE

English