3

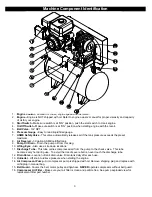

Machine Component Identification

1.

Engine Control

- Location of choke, engine speed and fuel valve.

2.

Engine -

Engine is NOT shipped with oil. Refer to engine owners’ manual for proper viscosity and capacity

of oil for your engine.

3.

Start Switch -

Make sure switch is at “ON” position, push the start switch to crank engine.

4.

On/Off Switch -

Make sure switch is at “ON” position when starting engine with the recoil.

5.

Ball Valve

- 3/4” NPT.

6.

Pressure Gauge -

Easy to read liquid filled gauge.

7.

ASME Safety Valve

- This valve automatically releases air if the tank pressure exceeds the preset

maximum.

8.

Air Receiver -

30 gallon ASME certified tank.

9.

Pump Oil Drain

– Drain the pump oil from this plug.

10.

Lifting Eyes

- Also use as tie down locations.

11.

Discharge Tube

- This tube carries compressed air from the pump to the check valve. This tube

becomes very hot during use. To avoid the risk of severe burns, never touch the discharge tube.

12.

Drain Valve -

Location of tank drain valve. Drain tank daily after each use.

13.

Unloader

- Lift knob to relieve pressure when starting the engine.

14.

Air Compressor Pump -

Air compressor pump is shipped with oil. Remove shipping plug and replace with

oil fill plug in manual bag.

15.

Belt Guard

- Covers the belt, motor pulley and flywheel.

NEVER

operate compressor without belt guard.

16.

Compressor Air Filter -

Make sure your air filter is clean and particle free. See pump exploded view for

replacement filter part number.