8785081

200A AC/DC Dial Control TIG Welder 202KE

V4.2

24

For technical questions call 1-800-665-8685

DISPOSAL

Recycle a tool damaged beyond repair at the appropriate facility.

Contact your local municipality for a list of disposal facilities or by-laws for

electronic devices, batteries, oil or other toxic liquids.

TROUBLESHOOTING

Visit a Princess Auto Ltd. location for a solution if the tool does not function

properly or parts are missing. If unable to do so, have a qualified technician

service the tool.

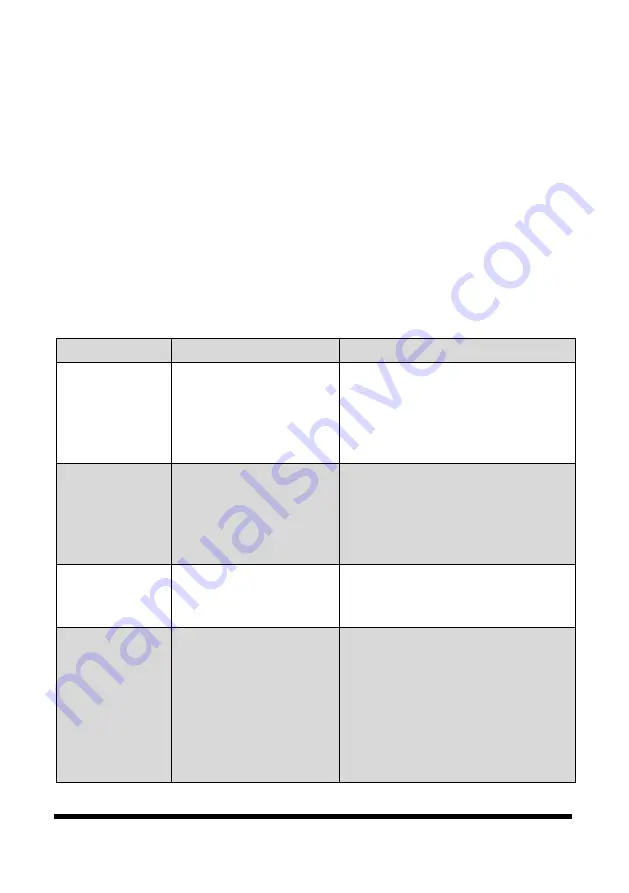

ARC (STICK) WELDING

Problem(s)

Possible Cause(s)

Suggested Solution(s)

No arc.

1. Incomplete welding

circuit.

2. Wrong mode selected.

3. No power supply.

1. Check earth lead is connected.

Check all cable connections.

2. Check that DC TIG (M) is selected.

3. Check that the machine is switched

on and has a power supply.

Porosity − small

cavities or holes

resulting from gas

pockets in weld

metal.

1. Arc length too long.

2. Workpiece dirty,

contaminated or

moisture.

3. Damp electrodes.

1. Shorten the arc length.

2. Remove moisture and materials like

paint, grease, oil and dirt, including

mill scale from base metal.

3. Use only dry electrodes.

Excessive spatter. 1. Amperage too high.

2. Arc length too long.

1. Decrease the amperage or choose a

larger electrode.

2. Shorten the arc length.

Weld sits on top,

lack of fusion.

1. Insufficient heat input.

2. Workpiece dirty,

contaminated or

moisture.

3. Poor welding technique.

1. Increase the amperage or choose a

larger electrode.

2. Remove moisture and materials like

paint, grease, oil and dirt, including

mill scale from base metal.

3. Use the correct welding technique

or seek assistance for the correct

technique.