PMAC Air Compressor

Powerex

•

100 Mundy Memorial Drive

•

Mt. Juliet, TN 37122

•

USA

P 1.888.769.7979

•

F 513.367.3125

•

www.powerexinc.com

IN598601AV

•

01/2020

Page 3 of 12

All electrical hook-ups must be performed by

a qualified electrician. Installations must be in

accordance with local and national electric codes.

Wiring

Use solderless terminals to connect the electric power source

provided. Various electrical connections may be provided in

accordance with customer requirements. Always ensure the

connections are proper and that when installing the final connection

that proper rotation of the compressor is witnessed.

Piping

Connect compressed air pipeline to the outlet of the check valve.

Do not modify check valve or replace with any other type. The scroll

compressor does not require a discharge pressure release valve for

shut down unloading. When the electric motor is de-energized, the

compressed air in the outlet pipe and after cooler will self relieve by

driving the pump in reverse a few turns. This is normal operation.

Do not modify or restrict the air flow to or from the after cooler

without review by Powerex Engineering. Improper cooling could lead

to damage of the scroll pump.

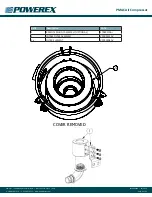

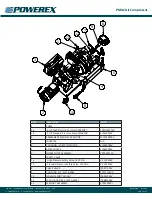

Direct Coupled Models

The Powerex Scroll Compressor assembly is designed to

accommodate a variety of mounting options by utilizing the main

baseplate. Standard mounting uses rubber stud isolation mounts.

Special models may vary.

Operation

Before Start-Up

1.

Make sure all safety warnings, labels and instructions have

been read and understood before continuing.

2.

Remove any shipping materials, brackets, etc.

3. Confirm that the electric power source and ground have been

firmly connected and are the correct voltage for the motor.

4. Be sure all pressure connections are tight.

5.

Check to be certain all safety relief valves, check valves, etc. are

correctly installed.

6.

Check that all fuses, circuit breakers, overloads, etc. are the

proper size.

7. Make sure the inlet filter is properly installed.

8.

Once power is connected to the unit, visually check the rotation

of the compressor pump. If the rotation is incorrect, have a

qualified electrician correct the motor wiring. Motor should

turn counter clockwise looking at motor end of cooling fan.

If pump is running in the wrong direction, change

the incoming power leads to correct rotation.

Operation in reverse for more than a few seconds will damage the pump

and is not covered under warranty.