16

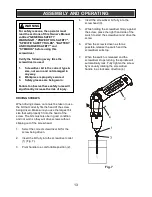

WARNING:

When servicing, use only original equipment replacement parts. The use of any

other parts may create a safety hazard or cause damage to the screwdriver.

Any attempt to repair or replace electrical parts on this screwdriver may create a safety hazard unless

repairs are performed by a qualified technician. For more information, call the Toll-free Helpline, at

1-866-349-8665 (Monday through Friday 9am

– 5pm Eastern Time).

Always order by PART NUMBER, not by key number.

Key #

Part #

Part Name

Quantity

1

4100020019

Retaining ring

1

2

2040050040

Output shaft

1

3

2010080033

Self lubricating bearing

1

4

3160100001

Gear housing

1

5

2030020041

Clamping plate

1

6

4110090001

Pin

6

7

2010240008

Positioning ring

1

8

2010090017

Ring gear

1

9

1170070024

Driving block

1

10

2010010030

Powdered metal planetary gear

3

11

1170070017

Planetary carrier

1

12

3150030004

Plastic planetary gear

3

13

2010180025

Motor gear

1

14

4020010054

Screw M2.5X4.5

4

15

3150090013

Motor mounting flange

1

16

1039010002

Motor

1

17

4030010008

Screw ST2.5X8

2

18

2050070014

Connecting plate

2

19

4080020001

Ball

4

20

1130060006

PCB for switch

1

21

1060120001

Switch

1

22

1260030003

Battery pack

1

23

1130020002

Charging PCB

1

24

3010030005

Enclosure

1

25

4030010034

Screw ST2.9X16

9

26

4030010130

Screw ST2.9X25

4

27

3110010031

Decoration button

1

28

4030020039

Screw ST2.5X8

2

PARTS LIST

!

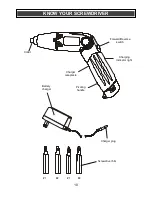

Summary of Contents for JD500203

Page 15: ...15 EXPLODED VIEW ...