5

Power-Flo Pumps & Systems • 877-24PUMPS • www.powerflopumps.com

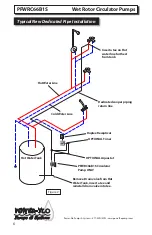

Installation

Pump Mounting

Arrows on the pump chamber indicate

direction of flow through the pump.

The pump can be mounted vertically free of

stresses from piping system with the pump

shaft in the horizontal position.

NEVER install the pump with the shaft

vertical or where the shaft falls below the

horizontal plane.

Provide support to the pump or adjacent

plumbing to reduce thermal and mechanical

stress on the pump.

Installation Requirements

1. Thoroughly clean and flush the system prior

to pump installation.

2. Do not install the pump at the lowest point

of the system where dirt and sediment collect.

3. Ensure that water does not enter the

terminal box during the installation.

4. (Open System) Install the pump in the

supply line; the suction side of the pump

should be flooded with water. Ensure that the

static head requirement from chart is achieved.

5. If there are execessive suspended particles

in the water, it is recommended that a strainer

and/or filter be installed and cleaned regularly.

6.

DO NOT START THE PUMP UNTIL THE

SYSTEM HAS BEEN FILLED.

Start-Up

Do not use the pump to vent the system. Do

not start the pump before filling the system.

NEVER OPERATE THE PUMP DRY

.

Electrical:

This pump will come equipped with a 6 Ft.

long soft jacketed 3 prong electric cord and

strain relief connection for “outlet plug in”

installations. The pump must be within 6 foot

of a 115 volt receptacle.

Operating voltage and other electrical

data can be found on the nameplate. All

models have thermal protection and require

no additional external protection. The

temperature of the winding will never exceed

allowable limits, even in locked rotor.

Operation

These circulating pumps will operate quietly

and efficiently and provide years of service if

sized for correct performance and installed

properly. Under

NO

circumstances should the

pump be operated without water circulation

or without the minimum required inlet

pressure for prolonged periods of time. This

could result in motor and pump damage.

Failure To Operate

When the pump is first started, the shaft may

rotate slowly until water has fully penetrated

the bearings. If the pump does not run, the

shaft can be rotated manually. To accomplish

this, switch off the electrical supply and close

the isolation valves on each side of the pump.

Remove the indicator plug in the middle of the

nameplate. Insert a small flat blade screwdriver

into the end of the shaft and gently turn until

the shaft moves freely. Replace and tighten the

plug. Open the isolation valves and wait 2 to

3 minutes for the system pressure to equalize

before starting the pump.

Wet Rotor Circulator Pumps

PFWRC66B1S