Power-Flo Pumps & Systems • 877-24PUMPS • www.powerflopumps.com

4

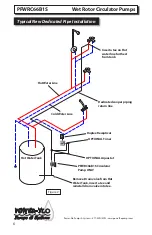

Installation

Pre-Installation

The following checks should be made before

beginning installation.

A.) Uses:

These pumps are generally

designed to circulate water from 32°F to

230°F and up to a maximum pressure of

145 psi. They are designed to be installed

in residential potable domestic hot water

systems to provide recirculation

(with a

dedicated recirculation pipe loop installed in

the system)

of domestic hot water resulting in

“instant” hot water at fixtures throughout the

house.

Open Systems:

These series pumps with

s

tainless steel or bronze pump housings are

designed to pump water compatible with

thier construction and can be used in both

open and closed systems.

B.) Maximum Water Temperature:

The

maximum allowable water temperature is

determined by the ambient or surrounding

air temperature. (See Figure 1)

C.) Inlet Pressure Requirements

The amount of pressure required at the inlet

of the pump is a function of the temperature

of the water as shown in the chart.

Inlet Pressure Requirements

Water (°F)

190 165 140

Required Inlet Pressure (ft)

5

4.5

3

(psi) 2.2

1.9

1.3

In a pressurized system, the required inlet

pressure is the minimum allowable system

pressure. In a system open to the atmosphere,

the required inlet pressure is the minimum

distance the pump must be located below

the lowest possible water level of the water

source.

Installation

Position of terminal box:

Proper installation

of the pump will have the terminal box

located to one side of the pump or the

other, with the conduit entry up. This is so

condensation does not run down the cord.

If the terminal box posistion needs to be

changed, it is best to do so before installation.

However, if the pump is already installed,

ensure that the electrical supply is turned

off and close any isolation valves before

removing the allen screws.

To change the terminal box posistion:

1. Remove the four (4) Allen screws while

supporting the stator.

2. Carefully separate the stator from the

pump chamber and rotate it to the correct

terminal box orientation.

3. Replace the Allen screws and tighten

diagonally and evenly to 7 ft-lbs.

4. Check that the impeller turns freely, if

not repeat the disassembly and reassembly

process.

t1 °F

35.6

104

140

176

194

212

221

230

t2 °F

32

104

140

176

158

140

131

93

Figure 1

t1 max: + 230°F

t2 min: + 35.6°F

PFWRC66B1S

Wet Rotor Circulator Pumps