Loading Fasteners

WARNING: Always disconnect the tool from the compressed air before

loading. When loading the tool always point the tool away from

yourself and others. Make sure that you are not holding the tool

with trigger depressed while loading the tool.

1. Insert a strip of fasteners into magazine, keeping it point down.

2. Release the latch and pusher, slid the pusher against the nails.

3. Connect the tool to the air supply. Make sure the air pressure is in the

correct range denoted in the Technical Data.

4. Then test the driving depth in a sample piece of wood before using. If the

fasteners are being driven too far or not far enough, adjust the regulator to

provide less air pressure or more air pressure.

5. Never operate tool unless safety nose is contact with workpiece. Do not

operate tool without fasteners or damage to tool may result.

6. Never fire fasteners into air because fasteners may injury operator or

others and damage to tool may result.

7. The tool is equipped with a single firing safety system to protect the

operator.

Maintenance

Disconnect the tool from the air compressor before adjusting, clearing jams,

servicing, relocating and during non operation.

1. Regular lubrication, if your tool without using the in-liner automatic oilier,

place 2 or 6 drops of pneumatic tool oil into the air inlet before each work

day or after 2 hours of continuous use depending on the characteristic of

workpiece or type of fasteners.

2. Check and change all worn or damaged o-rings, seals, etc. Tight all the

screws and caps in case personal injury.

3. Inspect trigger and safety mechanism to assure safe system is complete

and functional: no loose and missing parts, no building or sticking parts.

4. Keep magazine and nose of tool clean and free of any dirt lint or abrasive

particles.

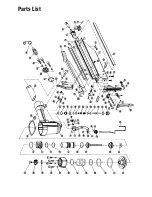

Summary of Contents for 8052409

Page 7: ...Parts List ...