Powered by Safety

®

36

Maintenance

01.4IB.50023A

PowlVac® Electrically Operated 15kV Ground and Test

per Long Island Railroad Specifications

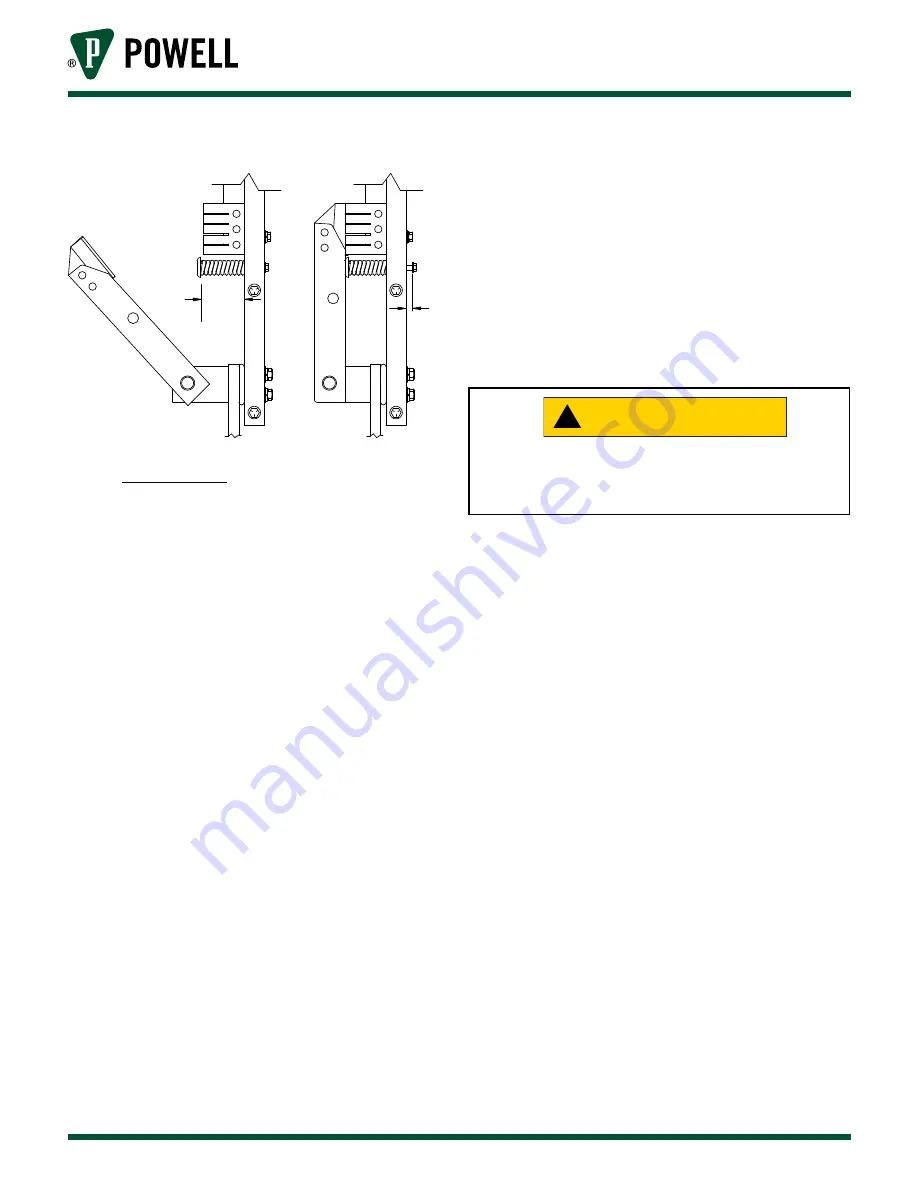

Figure 24 Ground Switch Contacts

2-1/8

1/4

to

5/16

c. Hinge Bolt

Disconnect the operating rod at the

movable contact by removing the pin.

With the movable contact not touching

the stationary contacts, apply a force

gauge to the outer end of the contacts.

should be

tightened so that the force necessary to

start the blades in motion is 9-12 lbs.

d. h

IGh

p

otentIAl

t

eStS

These tests are not ordinarily required for

routine maintenance, but should be performed

if the ground and test device has been in

storage for an extended period of time,

especially in a damp location or other adverse

environment, or if the insulation of the device

shows any signs of damage or deterioration.

1) High Voltage Insulation Integrity

With the grounding switch “

OPEN

” wire the

three upper primary stabs of the device to

a high potential test set and ground the

three lower primary stabs and the frame of

the ground and test device. Perform the

one minute high voltage test prescribed

in ANSI Standard C37.20.2, 5.5 and 4.2.3,

at the voltage level appropriate for the

equipment.

Remove all grounding conductors applied for

this test before placing the ground and test

device into service.

!

CAUTION

2) Control Voltage Insulation Integrity

If the user wishes to check the insulation

integrity of the control circuit, it may be

done with a 500V or 1000V insulation

tester or with and AC high potential tester.

The AC high potential test should be

made at 1125V, 60Hz, for one minute. The

charging motor must be disconnected at its

connection plug prior to testing the control

circuit. The motor itself may be similarly

tested at a voltage not to exceed 675V,

60Hz. Be sure to remove any test jumpers

and reconnect the charging motor when

the tests are complete.