Powered by Safety

®

25

Installation

01.4IB.60306

B. h

AnDlInG

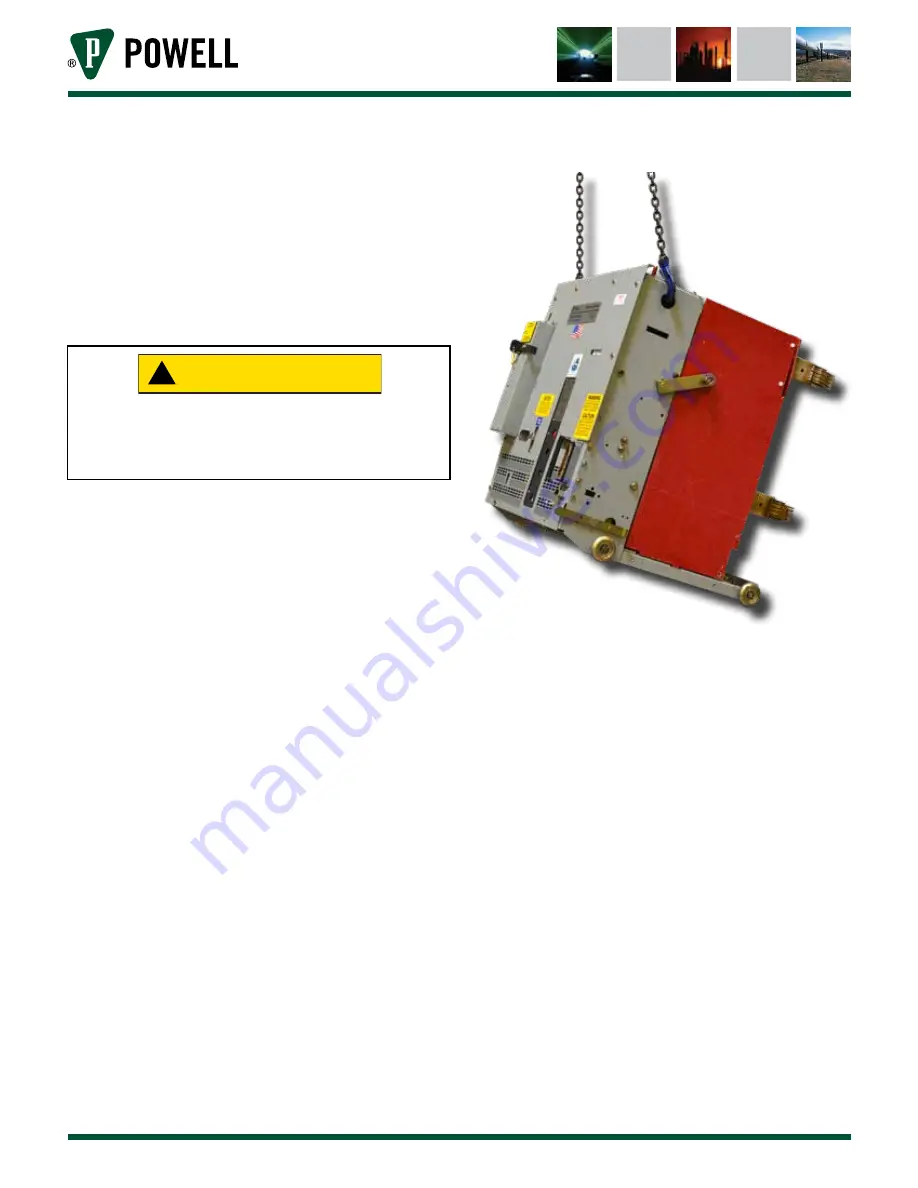

After the circuit breaker has been removed

from its shipping pallet it may be rolled on

its own wheels on a level surface. This is the

preferred way of handling the circuit breaker.

When rolling the circuit breaker it should be

pushed and steered by the steel frame or the

front cover.

Do not handle or move the circuit breaker by

the primary disconnecting devices, as damage

may occur.

!

CAUTION

If necessary, the circuit breaker can be moved

by a fork lift truck or an overhead crane.

When using a fork lift truck take care to avoid

components located under the circuit breaker

floor pan. The forks on the truck should be set

for a dimension over the forks of 28 inches.

The forks should then ride under the wheel

axles. The circuit breaker can also be lifted by

an overhead crane using the two lifting points

which have been provided for hooks at the top

of the circuit breaker frame side sheets

(

).

Figure 11 Circuit Breaker on Crane

c. S

torAGe

Shipping and storage of electrical equipment

requires measures to prevent the deterioration

of the apparatus over a long unused period.

The mechanical and dielectric integrity must

be protected. Electrical equipment is designed

for use in a variety of environments. When

the equipment is in transit and storage, these

design considerations are not fully functional.

In general, the following measures must be

considered.

1. Equipment designed for indoor installation

must be stored indoors in a climate

controlled environment to prevent

condensation of moisture. Exposure to rain

and the elements, even for a short period,

can permanently damage the equipment.

Space heaters within the equipment should

be energized, if so equipped. Humidity

controlling desiccant materials should

be utilized when space heaters are not