Power-Flo Pumps & Systems • 877-24PUMPS • www.powerflopumps.com

9

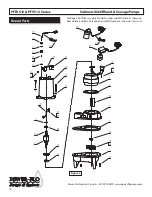

Power Cord:

8. Check power cord (19) for cracks

or damage and replace if required.

Reconnect motor leads.

9. Place power cord (19) with nylon

housing (15), ring (16), washer (17) and

gland nut (18) into housing (24) and

tighten gland nut to 17.5 ft/lbs.

Impeller, V-ring and Volute:

10. Position v-ring (35) into seal plate (3)

until seated.

11. Clean the threads with thread locking

compound cleaner. Apply removable

Loctite® 242 or equivalent to shaft

threads. Screw impeller (37) onto the shaft

hand tight while using a screwdriver in

the slot at the end of the shaft to hold it

stationary. Rotate impeller to check for

binding.

12. Position gasket (2) on volute flange

and position impeller and motor housing

assembly on volute (1).

13. Place screws (36 into volute (1) and

torque to 11 ft/lbs. Check for free rotation

of impeller.

14. Refill with cooling oil.

PFEV512 & PFV512 Series

Submersible Effluent & Sewage Pumps

Service

Risk of electric shock. Always disconnect the pump from the power source before handling inspections or repairs.

Symptom

Possible Cause(s)

Corrective Action

Pump will not run

1. Blown fuse or other interruption of

power; improper voltage.

2. Switch is unable to move to the “turn ON”

position due to interference with the side of basin

or other obstruction

3. Insufficient liquid level

4. Defective level control

1. Check that the unit is securely plugged in. Have an electrican check all

wiring for proper connections and adequate voltage and capacity.

2. Position the pump or switch so that it has adequate clearance for free

operation.

3. Make sure the liquid level is allowed to rise enough to activate level

control(s).

4. Remove and replace level controls

Pump will not turn off

1. Discharge is blocked or restricted

2. Check valve is stuck closed or installed

backwards

3. Gate or ball valve is closed

4. Total lift is beyond pump’s capability

5. Pump impeller is jammed or volute casing is

pluged

1. Check the discharge line for foreign material, including ice if discharge line

passes through or into cold areas

2. Remove check valve(s) and examine for freedom of operation and proper

installation

3. Open gate or ball valve

4. Try to route piping to a lower level.

If not possible, a larger pump may be required. Consult the factory

5. Disconnect unit electrically. Remove the pump from the basin. Detach the

pump base and clean the area around the impeller. Rotate impeller by hand.

Reassemble and reinstall

Pump will not turn off

1. Level control(s) unable to move to the “turn OFF”

position due to interference with the side of basin

or other obstacle

2. Defective level control

1. Posistion the pump or level control so that it has adequate clearance for

free operation

2. Remove and replace level control

Pump runs periodically

when fixtures are not in

use

1. Check valve is stuck open or is leaking

2. Fixtures are leaking

1. Remove check valve(s) and examine for freedom of operation and proper

installation

2. Repair fixtures as required to eliminate leakage

Pump operates noisily

1. Debris in the impeller cavity

2. Damaged impeller

3. Worn bearings

4. Piping attachments to building are too rigid

1. Remove the pump from the basin.

Detach the pump base and clean the area around the impeller. Reassemble

and reinstall

2. Consult the factory for information regarding replacement of impeller

3. Return pump to the factory or authorized repair station for repair

4. Replace a portion of the discharge line with rubber hose or connector

NOTE:

Power-Flo Pumps & Systems assumes no responsibility for damage or injury due to disassembly in the field. Disassembly of the pumps or supplied

accessories other than at Power-Flo Pumps & Systems or its authorized service centers, automatically voids warranty.

Trouble Shooting Chart