Part No. 27/20334

Component Replacement 39

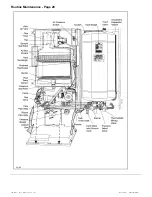

Component Replacement - Page 39

6.21

Automatic Air Vent

(See Fig. 30)

a. Remove the white front case, base panel and white left

hand side panel. See 5.1, 5.2 & 5.3 in 'Routine

Maintenance'.

b.

Close the central heating isolating valves, reduce the

system pressure by opening the pressure relief valve,

then part drain the water from the boiler by opening the

bleed valve on the right hand side of the diverter valve.

c.

Using a spanner to prevent the retaining nut from

rotating unscrew the auto air vent and remove from the

appliance. If there is insufficient space, removal will be

eased if the complete auto air vent and pipe assembly

is disconnected from the heat exchanger and then

raised above the top of the air box. To do this the fan

and fluehood will need to be removed, see 5.4 & 5.5 in

‘Routine Maintenance’

d. Fit new air vent and sealing washer

ensuring the air

vent cap is left loose.

Re-assemble in reverse order, ensure that the

grommet is correctly positioned. Re-charge the system

as described in section 1.6 and check for leaks.

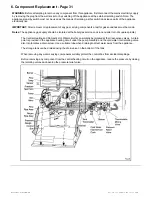

6.22

Pressure Relief Valve

(See Fig. 31)

a.

Remove the white front case and base panel.

See 5.1 & 5.2 in ’Routine Maintenance’.

b.

Close the central heating isolating valves, reduce the

system pressure by opening the pressure relief valve,

then drain the water from the appliance by removing

the drain off screw on the underside of the pump

manifold.

c.

Undo the outlet tube nut and fully remove the two grub

screws holding the pressure relief valve to the pump

manifold, undo the top compression joint on the

pressure relief valve discharge pipe then remove the

valve.

Note:

The outlet of the pressure relief valve is an olive

connection.

d.

Fit the new pressure relief valve using a new ‘O’ ring

seal and soap solution as a lubricant. Re-assemble in

reverse order.

e.

Recharge the system as described in section 1.6 and

check for leaks.

Summary of Contents for Puma Flowsure+

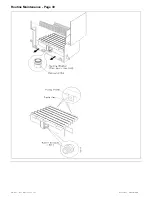

Page 5: ...Part No 27 20334 Introduction 5 Introduction Page 5 ...

Page 28: ...28 Routine Maintenance Part No 27 20334 Routine Maintenance Page 28 ...

Page 30: ...30 Routine Maintenance Part No 27 20334 Routine Maintenance Page 30 ...

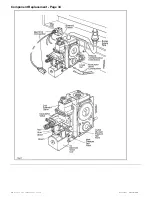

Page 34: ...34 Component Replacement Part No 27 20334 Component Replacement Page 34 ...

Page 42: ...42 Control Flow Sequence Part No 27 20334 8 Control Flow Sequence Page 42 ...

Page 43: ...Part No 27 20334 Functional Flow 43 9 Functional Flow Page 43 ...

Page 44: ...44 Pictorial Wiring Diagram Part No 27 20334 10 Pictorial Wiring Diagram Page 44 ...

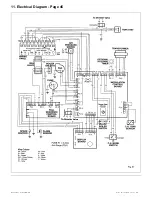

Page 45: ...Part No 27 20334 Electrical Diagram 45 11 Electrical Diagram Page 45 ...

Page 47: ...Part No 27 20334 Short List of Spares 47 Short List of Spares Page 47 Back page ...