PRINTED IN USA

PAGE 3 OF 6

AUTO TEST VSR (VSR-AT)

VANE TYPE WATERFLOW ALARM SWITCH WITH

ELECTRONIC RETARD AND AUTO TEST FEATURE

MFG. #5401239 - REV B

3/14

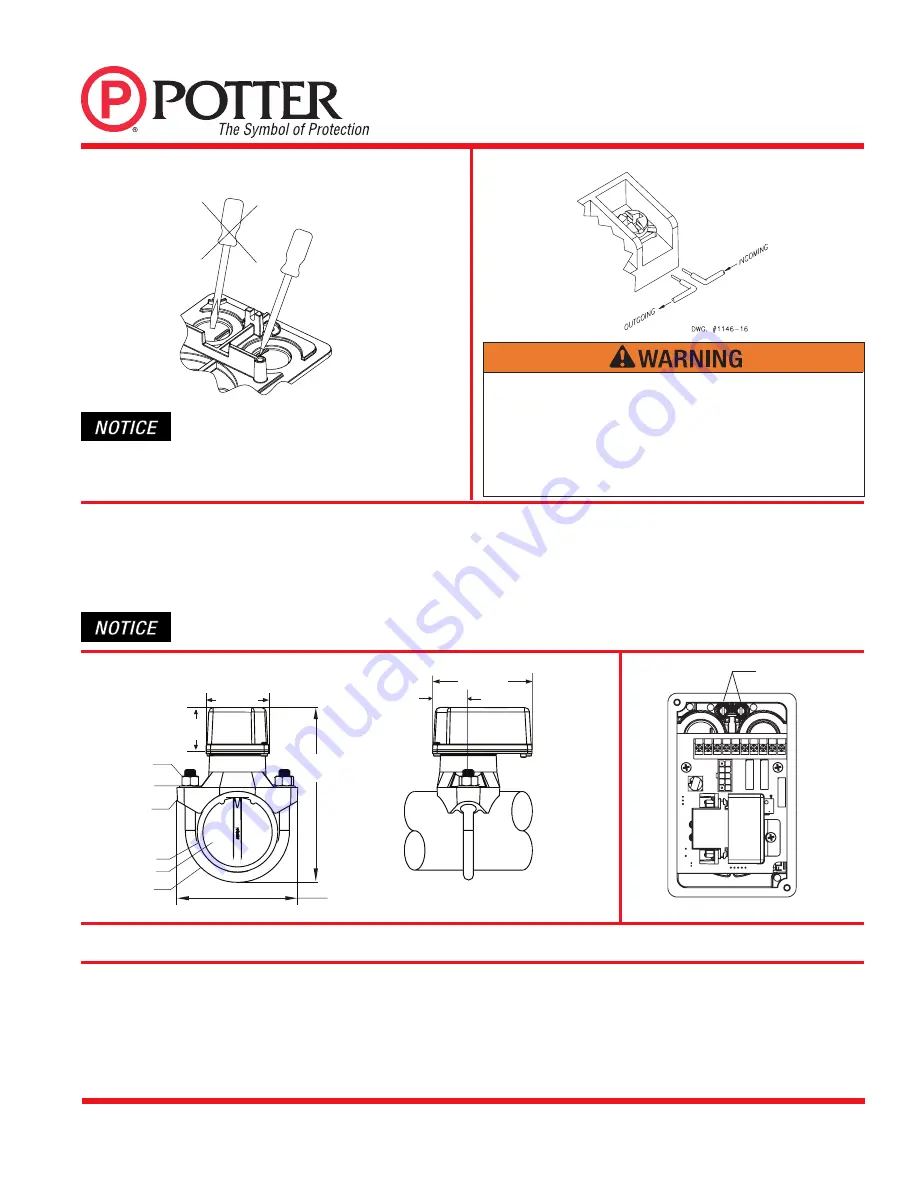

Removal of Waterflow Switch

•

To prevent accidental water damage, all control valves should be shut tight and the system completely drained before waterflow detectors are

removed

or

replaced.

• Turn off electrical power to the detector, then disconnect wiring.

•

Loosen

nuts

and

remove

U-bolts.

• Gently lift the saddle far enough to get your fingers under it. With your fingers, roll the vane so it will fit through the hole while continuing

to lift the waterflow detector saddle.

• Lift detector clear of pipe.

To remove knockouts: Place screwdriver at inside edge of knockouts, not in

the center.

DWG 1146-4

Fig. 2

Do not drill into the base as this creates metal shavings which can

create electrical hazards and damage the device. Drilling voids the

warranty.

Fig. 3 Switch Terminal Connections Clamping Plate Terminal

An uninsulated section of a single conductor should not be looped around the

terminal and serve as two separate connections. The wire must be severed,

thereby providing supervision of the connection in the event that the wire

become dislodged from under the terminal. Failure to sever the wire may

render the device inoperable risking severe property damage and loss of life.

Do not strip wire beyond 3/8" of length or expose an uninsulated conductor

beyond the edge of the terminal block. When using stranded wire, capture all

strands under the clamping plate.

Maintenance

Inspect detectors monthly. If leaks are found, replace the detector. The VSR-AT waterflow switch should provide years of trouble-free service.

Fig. 4 Mounting Dimensions

DWG. 1146-14

3.50 in

(89.0 mm)

2.34 in

(59.4 mm)

PIPE DIA.

+ 5.25 in

(+ 133.4 mm)

5.56 in

(141.2 mm)

2.00 in

(50.8 mm)

U-BOLT NUT

U-BOLT WASHER

PIPE SADDLE

PIPE

PLASTIC PADDLE

U-BOLT

NOMINAL PIPE DIA. +1.75 in (+44.5 MM) FOR DN 50 – DN 65 2–2.5 in

NOMINAL PIPE DIA. +2.125 in (+54.0 MM) FOR DN 80 – DN 200 3–8 in

Fig. 5

GREEN GROUND

SCREWS

Testing

The frequency of inspection and testing for the Model VSR-AT and its associated protective monitoring system shall be in accordance with applicable

NFPA Codes and Standards and/or the authority having jurisdiction (manufacturer recommends quarterly or more frequently).

An inspector’s test valve shall be provided for commissioning and test purposes when required by the AHJ. If there are no provisions for testing

the operation of the flow detection device on the system, application of the VSR-AT is not recommended or advisable.

A minimum flow of 10 GPM (38 LPM) is required to activate this device.

Advise the person responsible for testing of the fire protection system that this system must be tested in accordance

with the testing instructions.