Page 8

Power On

When all the above cable connections are made correctly, you may connect

your power adaptor to the wall outlet. Make sure that the type of power cord to

meet the local power conditions. Now the printer is ready for power on.

Self Test

Press and hold down the feed button while turning on

the power switch. The printer will then perform a self-

test mode. A sample slip of self-test result is printed as

in the sample at right. Please note that both serial and

parallel interfaces are indicated. That means the printer

is working on an auto-sensing and auto-select

algorithm.

The header is printed in text mode and the rest part of

this slip is printed in page mode. If FEED button is

pressed at this moment, a font table will be printed in

text mode again. To exit the test printing, please turn

the printer off and on again.

SPECIAL ADJUSTMENTS

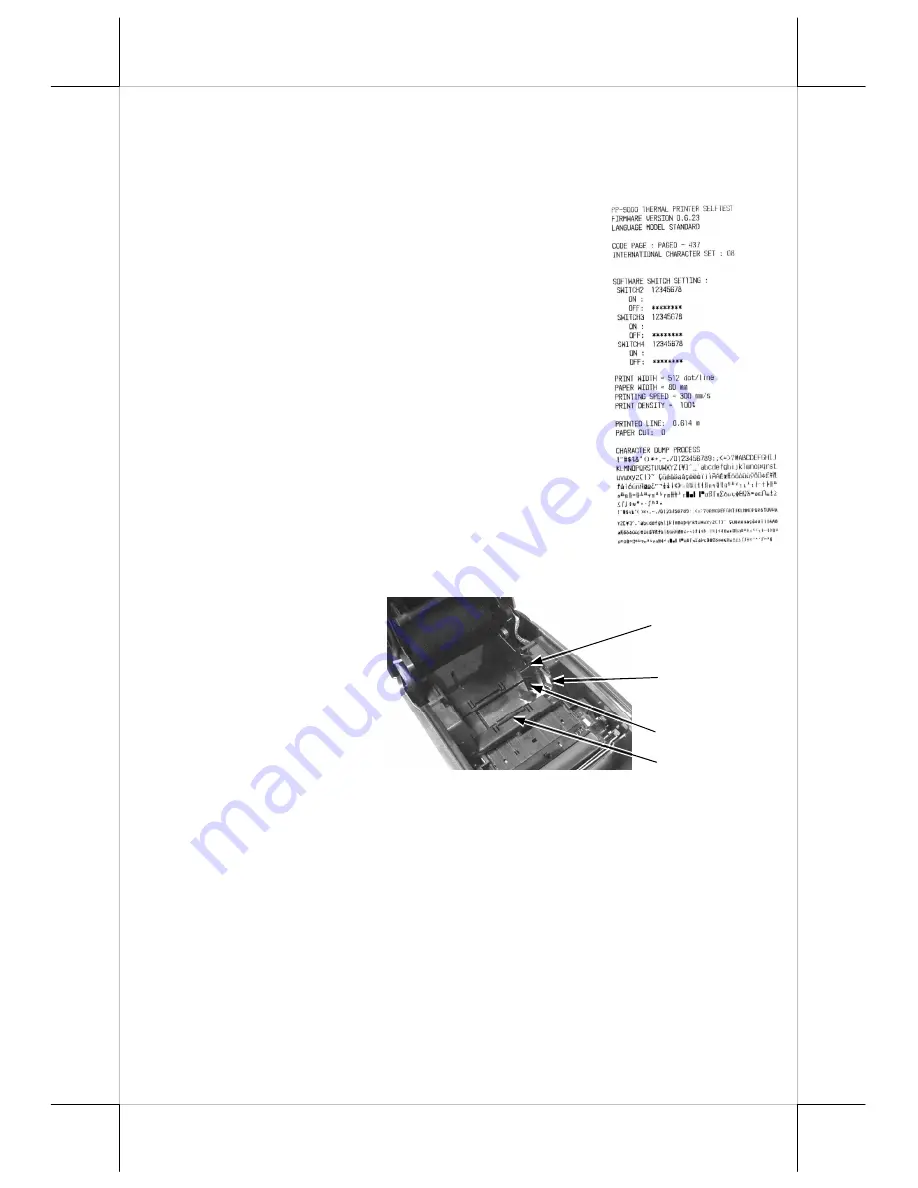

Paper Near End Sensor

The near end sensor for

paper roll in the printer is

able to have the printer

work with paper rolls of

several bobbin sizes. Please

refer to the picture at right

for the inside of the paper

roll compartment that there

are a plastic thumb for bobbin size adjustment and a sensor block in the wall.

Adjust the thumb to change the proper position of sensor block. For desktop

application, the sensor block should be above the bobbin seating of paper

compartment when paper near end. The acceptable paper roll bobbin outer

diameter is between 18 and 24 mm.

58mm Paper Spacing Plate

The application of 58 mm wide paper roll in this printer can be achieved

through adoption of an option spacing plate and an internal DIP switch or

software switch setting. Please refer to the last chapter of this manual for the

DIP switch setting as well as refer to the upper picture above for install the 58

mm paper spacing plate.

Sensor Position

Adjust

Sensor Block

Paper Roll

Shaft Hold

Support Roller