Page 17

for not busy. When it is set to OFF, the printer signifies the busy status over

hardware signals that can be detected by the host as “DTR” or “DSR”.

For switch position 5, if the switch is set to ON, the busy signal is sent to host

only when input buffer is full. When it is set to OFF, busy signal is sent to host

whenever an off line status occurs. Therefore, signals including the paper near

end detect will generate busy signal to the host. Consequently, the printing

may be stopped even when there is still a long way to go before the paper roll

is actually exhausted. Taking the paper out beep into consideration, the printer

will keep on beeping at Paper End (completely no paper) till paper is replaced

when S1-5 is ON. Yet when S1-5 is OFF, the printer will keep on beeping

every 3 seconds at Paper Near End (still long paper in replace) till paper is

replaced.

For switch position 6, when it is set to OFF, there will be a 12.5 mm paper

feed before cutting when software does not define this point and there will be

further 2 mm paper after cutting to prevent paper jam. Before setting this

switch to ON, please make sure that your software will take care of enough

paper feed for the paper jam prevention issue.

For switch position 7, when it is set to ON, the printer responds to a

carriage return command (CR code or 0Dh) with also a line feed (LF code or

0Ah) action. Then if the text editor always express the change to a new line

with both the CR and LF codes, there will be an extra line advance than

expected. However it works for some old editors that express the change to a

new line with only either one of the LF code or the CR code.

Switch position 8 defines the firmware update function. If the printer

needs to update the firmware, please set to “ON” position. In order to

operating perfectly, please set in “OFF” when the printer do not needs to

update the firmware or in normal situation.

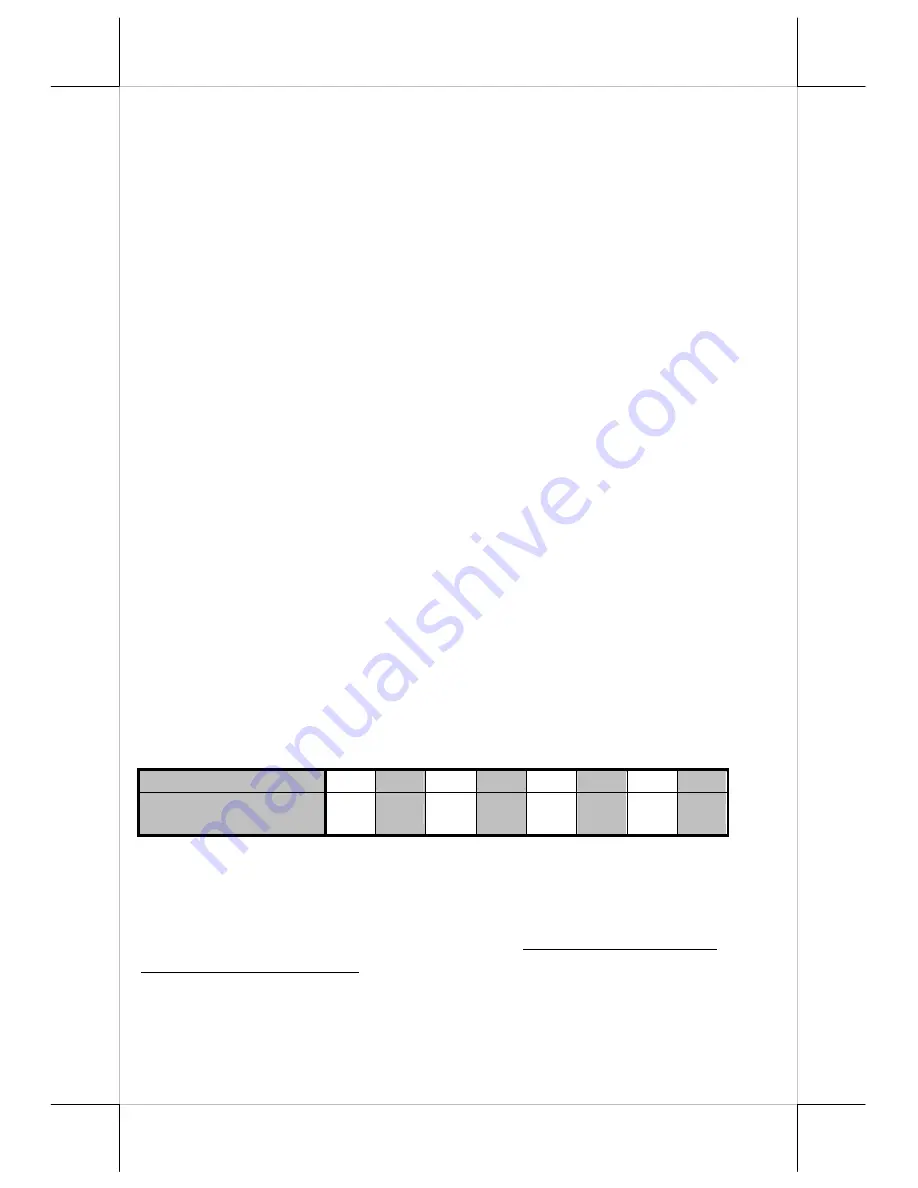

The factory default for each position listed as below:

Switch 1 Position

1

2

3

4

5

6

7

8

Default setup for Aura-

5200E

OFF OFF OFF OFF OFF OFF OFF OFF

Software switch

Another method to setup Aura-5200E series is through the software switch

setting, which means other functions must be change by software utility.

Please

visit

our

web

site

http://www.posiflex.com

or

http://www.posiflex.com.tw

to download the

Aura-5200E software switch

utility.

Software switches has divided into

SW2 and

SW3

Following

information is going to describe these settings.