15 - ENG

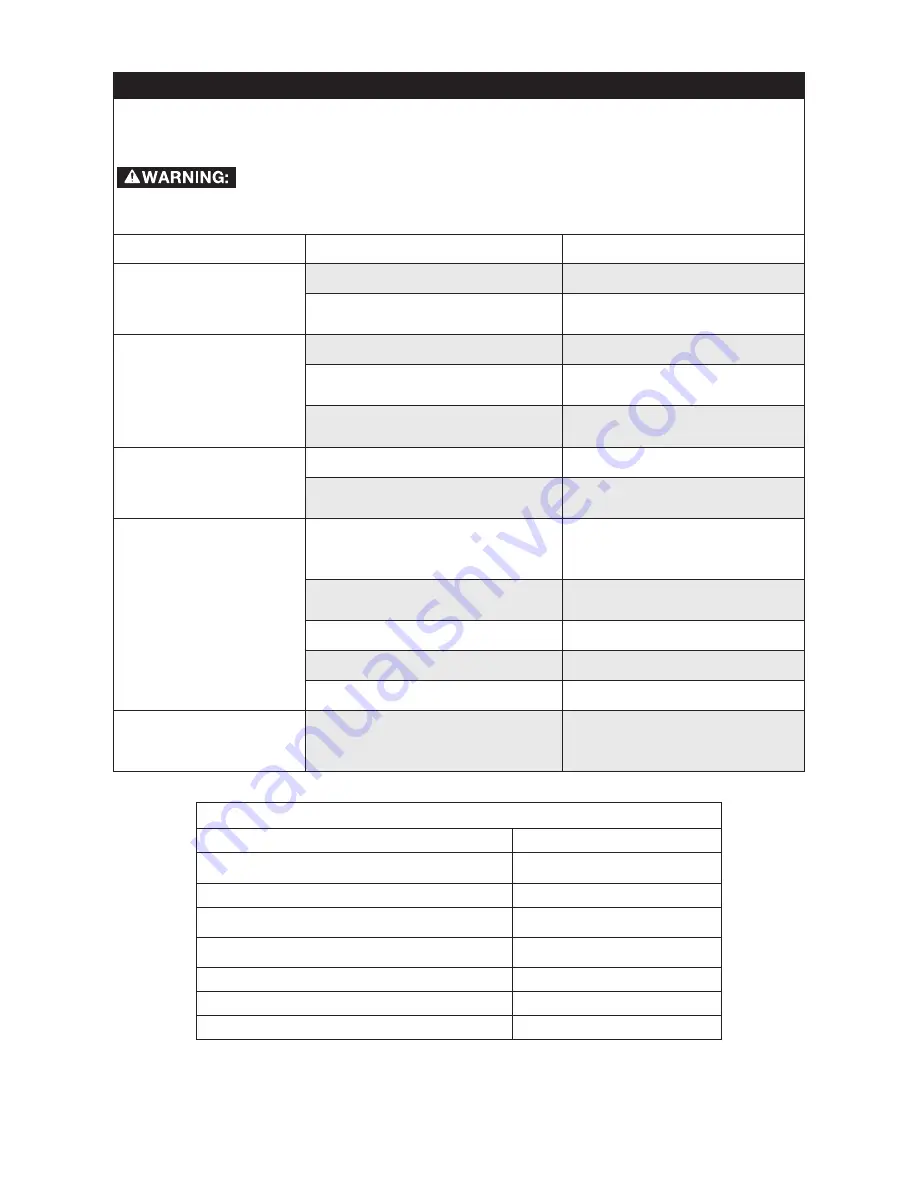

TROUBleSHOOTInG GUIDe

MANY COMMON PROBLEMS CAN BE SOLVED EASILY BY UTILIZING THE CHART

BELOW. FOR MORE SERIOUS OR PERSISTENT PROBLEMS, CONTACT A PORTER-

CABLE SERVICE CENTER OR CALL 1 888 848-5175.

To reduce the risk of serious personal injury, AlWAyS disconnect

air from tool and engage trigger lock, before all repairs.

SyMpTOM

pROBleMS

SOlUTIOnS

Air leak near top of

tool or in trigger area

Loose screws.

Tighten screws.

Worn or damaged

o-rings or seals.

Install Overhaul Kit.

Tool does nothing or

operates sluggishly

Inadequate air supply.

Verify adequate air supply.

Inadequate lubrication.

Put 5 or 7 drops of

oil into air inlet.

Worn or damaged

o-rings or seals.

Install Overhaul Kit.

Air leak near

bottom of tool

Loose screws.

Tighten screws.

Worn or damaged

o-rings or bumper.

Install Overhaul Kit.

Tool jams frequently

Incorrect fasteners.

Verify approved fasteners

of correct size and 34°

collation angle.

Damaged fasteners.

Bent collation wire.

Replace with undamaged

fasteners.

Canister or nose screws loose Tighten screws.

Canister is dirty.

Clean magazine.

Driver tip is worn or damaged. Install Driver Maintenance Kit.

Other

Contact a PORTER-CABLE

Authorized Warranty

Service Center

TOOl SpeCIFICATIOnS

FC350B

Height (inch/mm)

14.76/375

Width (inch/mm)

4.72/120

length (inch/mm)

19.09/485

Weight (lbs/kg)

7.28/3.30

Recommended Operating pressure 70-120 psi (4.8 to 8.3 bar)

Air Consumption per 100 cycles

9.74 CFM

loading capacity

80 nails