18

POLYPRINTDTG.COM

QUICK USER GUIDE

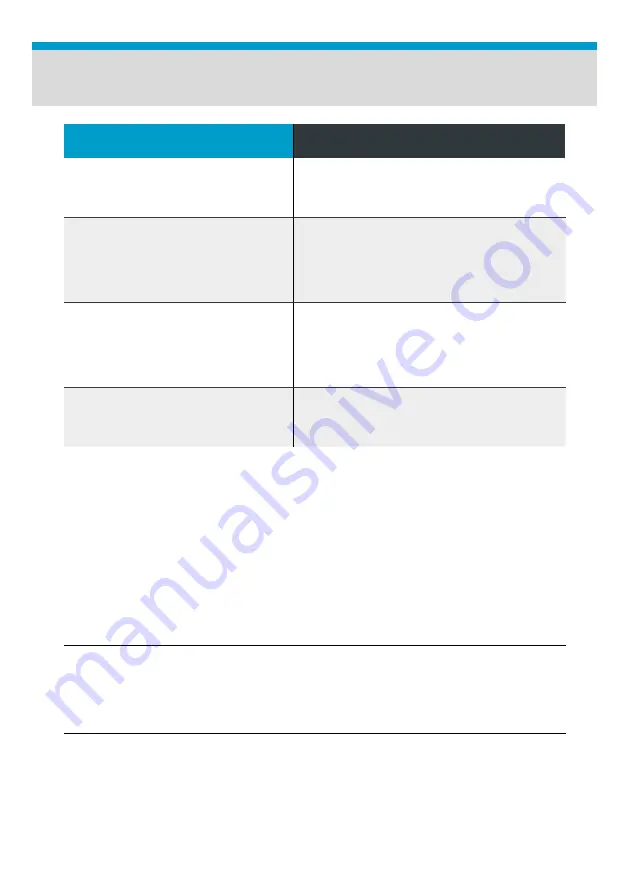

Troubleshooting

ERROR CODES

Action

1601 / 122

If error is displayed during maintenance

procedure, make sure Print Head is

locked

. Restart Printer.

1404

Air Leak.

Make sure all the cartridges are

properly inside the ink system slots.

In case of using sealed cartridges make

sure Cartridges are not completely empty.

Restart TexJet® echo².a

1401

Restart Printer.

When the Notice message

appears, press Proceed at the first two

screens. At the Continue Printing question

tap NO. Reset cartridge Chips. (page 9)

Restart printer.

PLATEN IS

NOT MOVING

Check if Emergency Button is at lock

position. Restart TexJet® echo².

In case a good nozzle test print (no visible gaps or missing lines and

vibrant test patterns) cannot be achieved, follow the steps below.

Ink Flow Troubleshooting

|

01

_STEP

Ensure capping station and wiper are clean. If they have dried ink, head

cannot lock properly on it and cleaning has no effect.

|

02

_STEP

If the issue occurs in only one channel, follow instructions on cleaning its

cartridge, page 8. If using sealed cartridge, replace it.

|

03

_STEP

Follow Weekend maintenance but instead of cleaner, use isopropyl alcohol.

After 10min, restart Printer and perform a Powerful Head Cleaning.

Summary of Contents for TexJet echo2

Page 1: ...QUICK USER GUIDE...

Page 23: ...Notes...

Page 24: ...www polyprintdtg com POLYPRINTDTG 2021 02 12_TEXJET ECHO_UG_EN_V3 3...