DD-75-181 R(2)

Y.T.13.07.17

6

2.3 Safety Related Instructions

1.

Users must not dismantle the turnstiles. Maintenance can only be performed by competent and authorized

personel. Maintenance work attempted by non- qualified individuals may create danger to users and the turnstile.

2.

Turnstile must not be installed at places where there is a risk of explosion caused by electrical arcs or a probable

gas leakage.

3.

Turnstile must be kept away from flammable environments.

4.

Turnstile should not be installed at places where there is vibration.

5.

Turnstile must not be kept in excessively moist environments.

6.

Turnstile must not be exposed to heat.

7.

Turnstiles must not be subjected to abusive treatment such as impact or excessive shaking.

8.

Turnstile must be kept away from high level magnetic fields.

9.

Operating voltage/ power range must be observed in all installations. .

10.

The power must be stable, properly grounded, insulated.

11

. Turnstiles can only be operated under the environmental conditions and temperatures specified by the manufacturer.

12.

Children must not be allowed to play with the turnstiles.

13.

All connections must be confirmed to be correct before supplying power to the turnstile.

14.

Only materials and equipment recommended by the manufacturer must be used for the turnstile when making

connections into the input and output terminals.

15.

All parts and accessories used in the turnstiles must be approved by the manufacturer.

16.

In case of any electrical arching or faults caused by such condition, power must be disconnected and authorized

servicer or manufacturer must be contacted as soon as possible.

17.

The power must be cut off before cleaning or maintenance.

18.

Only clean, soft and moist fabrics (no abrasive materials or chemicals) should be used for cleaning the turnstile.

19.

Damaged turnstiles must not be operated, and the authorized dealer or the Manufacturers technical support

center should be contacted soon as possible for repair.

2.4 Operating Conditions

1.

More than one person must not attempt to pass at the same time.

2.

Turnstile must not be forced, kicked, abused or tempered with to gain passage without authorization.

3.

Turnstiles must not be washed for cleaning purposes (applying water with a hose or pouring water from a bucket etc.).

Wiping off with non-abrasive materials such as a soft and clean damp cloth is sufficient in most cases.

4.

Chemicals and abrasives must not be used in any case for cleaning. The manufacturer is not responsible for damages

resulting from use of such materials.

3. HANDLING AND INSTALLATION

3.1 Handling

1.

Please pay special attention to carry the turnstiles as originally packed by the manufacturer.

2.

Follow the handling and carrying instructions written on the package.

3.

Do not place a heavy load on the turnstile package.

4.

Do not place the packed turnstile on a wet ground.

5.

Do not leave the packed turnstile under rain.

6.

During handling, use an appropriate lift/crane with

sufficient lifting capacity.

7.

Before starting installation ensure that there is no

shipping damage or missing parts and hardware inside

the package.

3.2 Installation

1.

The installation place should be selected

according to user’s requirements. This selection

should not prevent the smooth operation of the

turnstiles.

2.

Ensure that the installation surface is flat, even and of proper

strength. Flatten any uneven/ rough areas if necessary.

3.

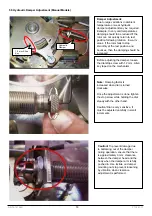

Mark the holes and drill with a 12 mm drill bit. Clean the

debris inside the holes by pressurized air.

4.

Fill the holes with chemical plaster and fix anchoring bolts

(10 mm) in place by rotating. Chemical plaster dries in about 25

minutes.

5.

Place turnstile on anchoring bolts and tighten the nuts to

secure in place.

6.

Connect power and control cables. Power and control cables

can be routed up through the structural pipes of the turnstile

using guide wires. Cable length extending from ground should

be at least 4 meters.

Note: A model specific mounting plan is supplied with each

turnstile.

MOUNTING DETAILS

GROUND PLAN

M10 NUT (CLOSED TOP)

M10 NUT

M10 LOCK WASHER

M10 WASHER

M10x200 STUD BOLT

TURNSTILE BODY

Chemical Anchor

GROUND

110 mm

60

mm

30

200 mm