Cardox Techical Manual

Page

13

male end of the clamp.

8.06 The clamp needs to be securely tightened in place on the tube. Hitting the clamp

with the wrench will verify that the clamp is in place securely.

8.07 When the base port is located close to a tower edge or corner wall only a 2-way

discharge head should be used. Mark the direction of discharge by aligning the

handle or the bolt on the clamp with the 2-way discharge outlet opening. When the

tube is locked in the base port, observe the direction the blast will go. Adjust the

positioning of the clamp so that the discharge will be in the vertical direction.

8.08 Next the firing wires should be placed in the activation auto fill head. The electrical

application is not polarity sensitive and as such no particular orientation of the firing

cable wires is needed. The opposite end of the firing cables should remain shunted

(twisted) together until the tube is placed in the base port, this prevents static elec-

tricity from the tube prematurely.

8.09 Place the tube with clamp into the base port and twist it into a locked position. Move

to the opposite end of the firing cable, which should be around a corner or out of

the line of the tube direction by 25’ – 30’. Hook up the MHSA approved blaster.

8.10 Observe that the area around the blast is secured. Hold the left button down on the

blaster until the red light comes on. Continue to hold the left button with the light on

and depress the right button to activate the safety heater inside the tube.

8.11 The blast should occur immediately. NOTE: the goal is to have the tube inside of

the tower heat for less than 5 minutes. Once the blast has occurred remove the

blaster and re-shunt that end of the firing cables.

8.12 If a blast does not occur, immediately approach the tube. Observe the location of

the relief hole in the fill head. Make certain that the relieved gas will not strike you in

the face. Open the safety bleeder valve using a 1/4” hex wrench. Let the gas bleed

off before removing the tube. Relieving this pressure will cause the inside of the

tube to go back to equal pressure with the outside. The heater in the tube cannot

function unless it has a constant pressure around it that is greater than 275 PSI.

After relieving the gas from inside of the tube will be less than the 275 PSI.

8.13 Remove the tube. Remember that by now the discharge end of the tube is very hot;

so handle accordingly.

8.14 This failed to blast tube should be marked properly or take it to the filling room and

carefully dismantle it according to section #6.03

Cardox Activation – KILN

8.15 To properly use Cardox to break up kiln build up rings – the base ports need to be

installed in the kiln wall while shut down in the locations that the ring is expected to

be based on past experiences.

8.16 The kiln can be drilled with it “hot” or “cold”. Proper precautions need to be taken to

work the kiln hot. The work can be done off a man lift machine or off a catwalk. The

kiln can be stopped for 15 – 30 minutes at a time and the hole drilled in the build

up. The kiln can then be rotated for the desired number of rotations.

Summary of Contents for Cardox CO2

Page 1: ...A B C D 8 7 6 TECHNICAL MANUAL 110 Mohr Drive Mankato MN 56001 1 800 458 9446 www pneumat com ...

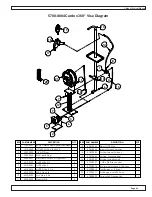

Page 22: ...Cardox Techical Manual Page 22 5780 0005 Cardox Fill Stand Assembly Parts List ...

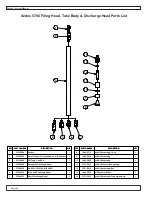

Page 25: ...Cardox Techical Manual Page 25 5730 0003 Auto Fill Activating Head w Eyebolt Parts List ...

Page 27: ...Cardox Techical Manual Page 27 Series 3700 Firing Head Tube Body Discharge Head Parts List ...

Page 28: ...Cardox Techical Manual Page 28 Series 5700 Firing Head Tube Body Discharge Head Parts List ...