Plasson Poultry Division, 105 Ilan St. P.O.B. 108 North Industrial Estate Or - Akiva 30600, Israel

Tel: +972-73-2413001 Fax: +972-73-2413221 E-mail: [email protected] www.plassonpoultry.com

03/11 - 6804

N i p p l e D r i n k e r S y s t e m I n s t a l l a t i o n M a n u a l

25.1

25

24.1

24

26

27

28

30

29

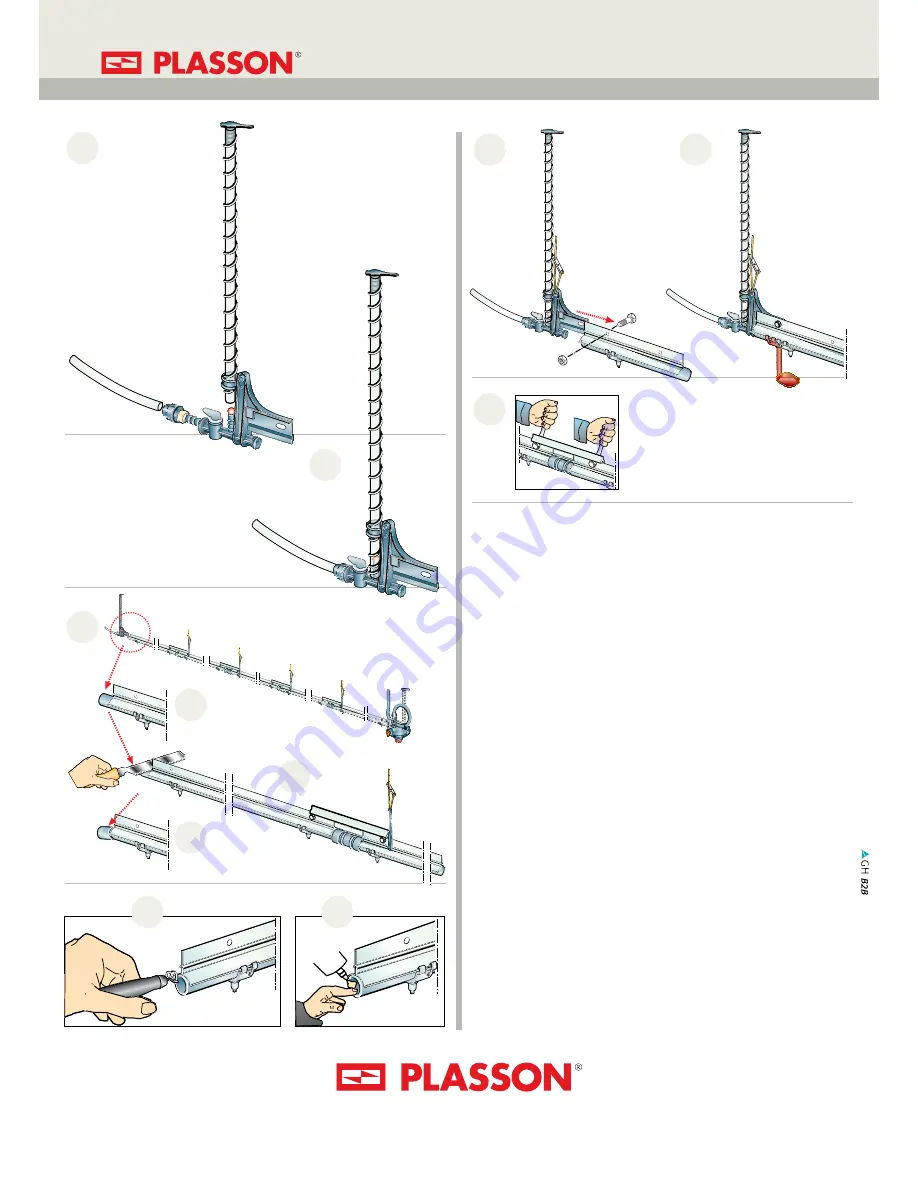

Install a suspension and winching system above the

chosen location of the line. Make sure all pulleys are

properly aligned at intervals not exceeding 3.0m (10')

and that the first pulley is located directly above the

beginning of the first section

• Filter must be installed before line header kit.

• If water is supplied from a header tank, the hight of

the header tank bottom must be at least 3 m (10')

above floor level.

• If water is supplied from a main pipe line, In-coming

pressure to header kit should be 1.5 bar (22 psi), max. 2

bar (30 psi).

• Lines must be level. Maximum permitted drop of line

without slope regulator: 15 cm (6").

• If there is a slope, the water inlets (line head kit) must

always be on the upper side.

• Maximum length of line: 120 m (400').

Some restrictions may apply in breeder, pullets and

turkey houses. See individual instructions.

• When using a shocker wire, install 4 suspension clips

per section.

• Lines should be parallel to the floor.

• Cord adjuster should be positioned near the aluminium

profile so that between flocks, the system can be raised

as close as possible to the ceiling.

• Before operating the system, the system must be

flushed thoroughly with high pressure.

General instructions

After the entire line has been

assembled, make sure it is properly

aligned, without distortions. Then

tighten up all the nuts on the

connecting pieces.

23

23.1

Global Presence - Local Commitment