DF500 Folder Operator Guide

16

SV40214 Rev. A

Folder Mechanics (continued)

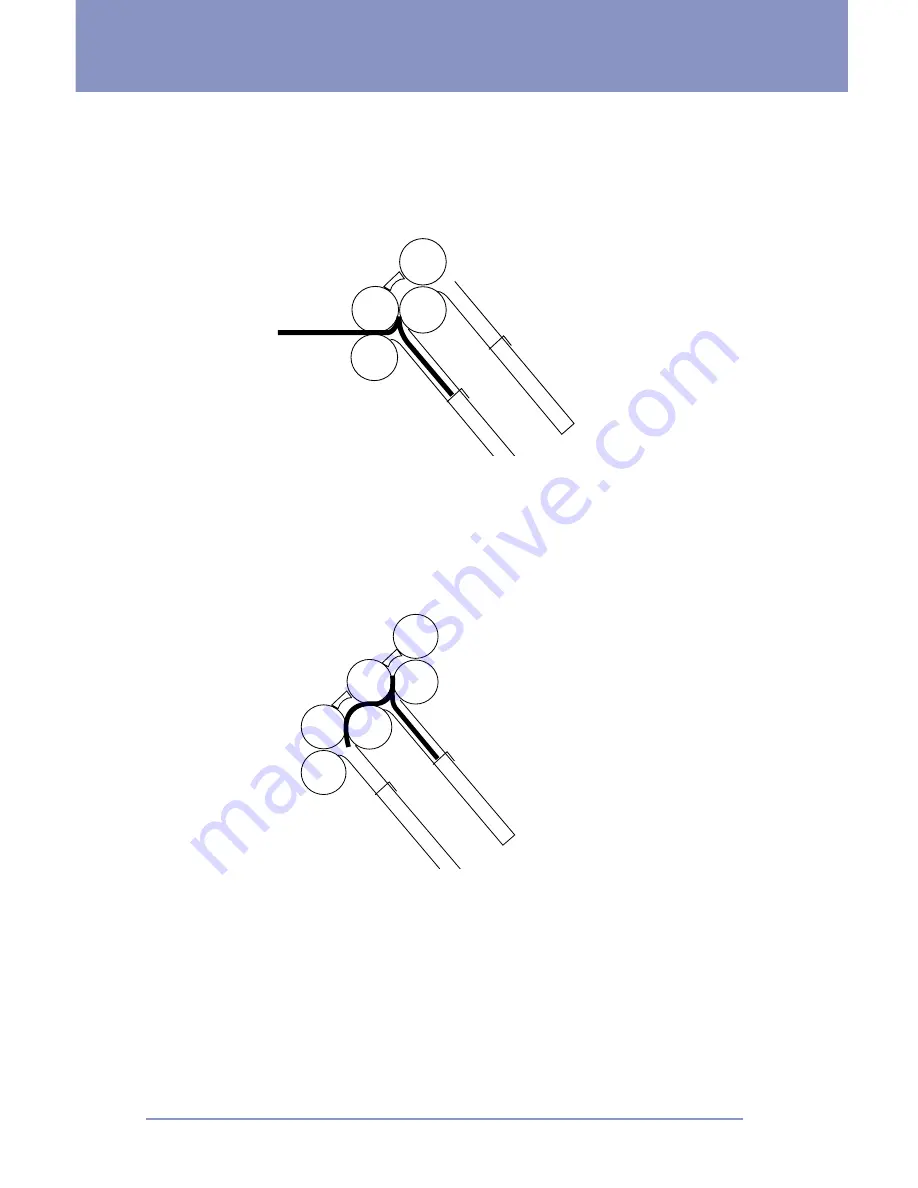

B. The paper con tin ues into the fold plate until it hits the stop.

Since the two rollers are still driving the paper, a buckle will

form at the en trance to the fold plate and will, eventually, be

caught be tween fold rollers (2) and (3). This is how the first

fold is made.

C. The folded edge will be guided by the deflector into the grip

of rollers (3) and (4). Here the same thing happens as in the

first fold plate and a second fold is made.

NOTE: If a single fold is selected, the second fold plate is au-

to mat i cal ly closed off and the folded sheet is routed past it.

1

2

3

4

1

2

3

4

5

6

D. The folded sheet is now guided by the second deflector into the

grip of rollers (5) and (6) where it is fed out onto the stacker.

It is obvious that the position of each fold plate stop determines

the length of the fold resulting from it. Keeping this in mind, it

is easy to make corrections to each fold by simply moving the

relevant stop in or out. You only need to know which end of the

sheet entered the machine first to recognize which was the first

fold and which was the second.