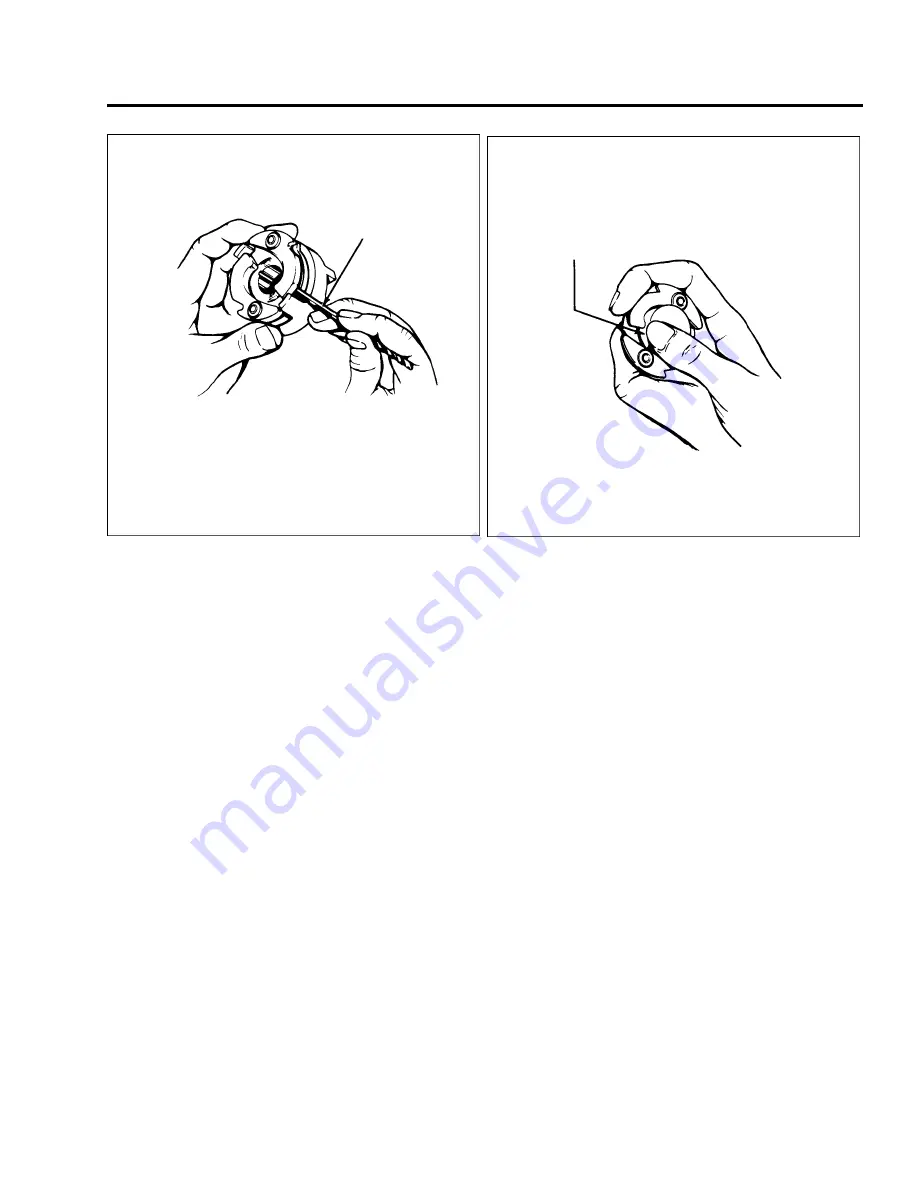

Figure 74-13. Checking Flyweight Axial Figure 74-14. Checking Flyweight Radial

Wear with Drill Shank Wear with Gauge

— NOTE —

A true and accurate check of the clearance between the flyweights and stop pins can

only be obtained by pulling the flyweight outward as described Do not attempt the

check by pushing in on the flyweight at point “A” of Figure 74-11.

2.

Inspect impulse coupling stop pins for damage. If pins are bent, damaged or excessively worn, remove pins

using a suitable drift and arbor press. Press new pins into flange until dimension shown in Figure 7412 is

obtained.

3.

Visually inspect flyweight securing washers and flyweights, particularly in area around the axle hole.for

cracks. Grip washers with pliers and exert moderate turning force to check looseness. If washer moves or

any cracks are found, reject cam assembly.

4.

Inspect for axial wear between flyweight and axle using shank of a new No. 35 drill as a gauge. Hold

flyweight so the outer radius is in alignment with the rim of the cam flange and try to insert the drill shank

between the flange and flyweight as shown in Figure 7414. Do not force the drill. If the drill can be

inserted, replace the cam assembly.

No. 35 DRILL

FLYWEIGHT

GAUGE 11-10041

PA - 4 4 - 1 8 0 / 1 8 0 T

AIRPLANE MAINTENANCE MANUAL

7 4 - 11 - 0 5

Page 74-15

Revised: May 15, 1989

3G8

PIPER AIRCRAFT

Summary of Contents for SEMINOLE PA-44-180

Page 38: ...CHAPTER DIMENSIONS AND AREAS 1B14...

Page 49: ...CHAPTER LIFTING AND SHORING 1C1...

Page 53: ...CHAPTER LEVELING AND WEIGHING 1C5...

Page 58: ...CHAPTER TOWING AND TAXIING 1C10...

Page 62: ...CHAPTER PARKING AND MOORING 1C14...

Page 65: ...CHAPTER REQUIRED PLACARDS 1C17...

Page 70: ...CHAPTER SERVICING 1C22...

Page 98: ...CHAPTER STANDARD PRACTICES AIRFRAME 1E2...

Page 108: ...CHAPTER ENVIRONMENTAL SYSTEM 1E12...

Page 189: ...CHAPTER AUTOFLIGHT 1H21...

Page 192: ...CHAPTER COMMUNICATIONS 1H24...

Page 202: ...CHAPTER ELECTRICAL POWER 1I10...

Page 228: ...CHAPTER EQUIPMENT FURNISHINGS 1J12...

Page 233: ...CHAPTER FIRE PROTECTION 1J17...

Page 238: ...CHAPTER FLIGHT CONTROLS 1J24...

Page 304: ...2A18 CHAPTER FUEL...

Page 325: ...2B17 CHAPTER HYDRAULIC POWER...

Page 357: ...2D1 CHAPTER ICE AND RAIN PROTECTION...

Page 414: ...CHAPTER LANDING GEAR 2F13...

Page 479: ...2I6 CHAPTER LIGHTS...

Page 488: ...2I16 CHAPTER NAVIGATION AND PITOT STATIC...

Page 503: ...2J7 CHAPTER OXYGEN...

Page 524: ...2K6 CHAPTER VACUUM...

Page 535: ...2K19 CHAPTER ELECTRICAL ELECTRONIC PANELS AND MULTIPURPOSE PARTS...

Page 546: ...INTENTIONALLY LEFT BLANK PA 44 180 180T AIRPLANE MAINTENANCE MANUAL 2L6 PIPER AIRCRAFT...

Page 547: ...2L7 CHAPTER STRUCTURES...

Page 582: ...CHAPTER DOORS 3A18...

Page 593: ...CHAPTER STABILIZERS 3B8...

Page 604: ...CHAPTER WINDOWS 3B22...

Page 611: ...CHAPTER WINGS 3C10...

Page 624: ...CHAPTER PROPELLER 3D1...

Page 643: ...CHAPTER POWER PLANT 3D21...

Page 667: ...CHAPTER ENGINE FUEL SYSTEM 3F1...

Page 681: ...CHAPTER IGNITION 3F16...

Page 712: ...CHAPTER ENGINE INDICATING 3H1...

Page 730: ...CHAPTER EXHAUST 3H19...

Page 734: ...CHAPTER OIL 3I1...

Page 743: ...CHAPTER STARTING 3I11...

Page 755: ...CHAPTER TURBINES 3J1...