7

This Machine is Manufactured for

Commercial use only.

This machine is designed and manufactured for

indoor use on hard floor surfaces. Amano Pioneer

Eclipse Corporation (APEC) does not recommend

use of this machine in any environment other than an

indoor environment. This floor machine is designed

and manufactured for commercial floor use only. This

machine is designed to clean most modern types of

floors including composition tile, stone, marble, terrazzo,

and resilient floor covering, and some coated wood

floors.

Operator Responsibility

The operator is responsible for performing the

recommended daily maintenance and checkups of the

machine to keep it in good working condition. The

operator must inform the service mechanic or supervisor

when recommended maintenance procedures are

required as prescribed in the

“MAINTENANCE”

section

of this manual.

FOR SAFETY:

DO NOT

operate machine before

reading and understanding the operation manual.

Keep your machine regularly maintained by following the

maintenance information in this manual. Order parts and

supplies only from an Authorized Amano Pioneer Eclipse

Distributor. Use the parts illustration section of your

manual when ordering parts.

During and after operation, perform the recommended

daily and hourly procedures outlined in the Maintenance

Chart.

Machine Preparation

Unpacking the Machine

When the machine is delivered, carefully inspect the

shipping carton and the machine for damage. Unpack

the machine with caution. If damage is evident, save the

shipping carton so that it can be inspected. Contact the

Amano Pioneer Eclipse Customer Service Department.

Transporting the Machine

To transport the machine, follow this procedure:

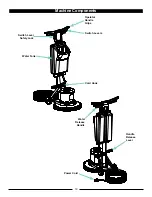

1. Raise and lock the handle in the upright position. To

lock the handle, push down on the handle release

lever (See Figure 1).

2. Unplug the machine from wall outlet and wrap cord

around the handle and cork hook.

3. To pick up the machine, using two people, lift and

place in cargo area (See Figure 2).

WARNING! The machine is heavy, 90 lbs (41 kg)

without the cord. To avoid injury or damage to

the machine use a firm grip and proper lifting

technique. Always use two people when lifting this

machine.

Person #1

Person #2

Figure 2

Figure 1

Summary of Contents for PE225FP

Page 1: ...1 Floor Polisher PE225FP Operator s Manual...

Page 13: ...13 Machine Troubleshooting Scheduled Maintenance...

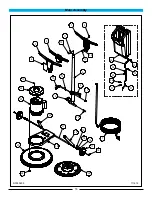

Page 15: ...15 Electrical Schematic 120V Electrical Schematic 127V 230V RF068800...

Page 20: ...20 Handle Assembly 225FP E E6 Models RF071600 060917 4 6 3 2 11 10 1 7 9 1 5 12 8...

Page 22: ...22 HANDLE ASSEMBLY 225FP17EB AND 225FP20EB MODELS RF066700...